How Much Does an Industrial Robot Cost?

Discover industrial robot costs in 2025: from $25K to $500K+. Explore pricing factors, types, integration costs, and ROI. Get a complete cost.

Industrial robot pricing has become a critical consideration for manufacturing facilities, logistics centres, and production environments seeking to enhance operational efficiency. How much industrial robots cost requires examining multiple factors that extend far beyond the base unit price. The global market for industrial automation solutions has experienced a significant transformation in recent years, driven by technological advancements and increased competition among manufacturers.

Industrial robot costs in 2025 range dramatically from approximately $25,000 for entry-level collaborative models to over $500,000 for fully integrated automated systems. According to recent market analysis, the average cost of an industrial robot system typically falls between $50,000 and $200,000 for the robot unit alone, with total implementation costs reaching $150,000 to $500,000 when including integration, safety systems, and training. This substantial investment represents a significant commitment that demands careful evaluation of long-term financial returns.

Robotics automation pricing varies considerably based on robot type, payload capacity, reach specifications, precision requirements, and intended applications. Small to medium-sized businesses exploring affordable robotic solutions can find entry-level collaborative robots starting at $25,000, while advanced industrial automation systems with specialised features command premium pricing. The democratisation of robotics technology has made automation investment increasingly accessible to companies of various sizes, fundamentally changing how modern manufacturing operations function.

This comprehensive guide explores the multifaceted aspects of industrial robot pricing, examining cost drivers, implementation expenses, and financial considerations essential for making informed automation decisions. Whether you’re considering cobot costs, articulated robot pricing, or the complete cost of industrial robotics, this article provides actionable insights for your specific situation.

Industrial Robot Costs in 2025

- Industrial robot pricing structures have evolved considerably as manufacturers compete to capture market share. The base cost of industrial robots depends primarily on their classification, technical specifications, and intended use cases. Collaborative robots (often called cobots) represent one segment, while traditional industrial robot arms occupy another, each with distinct pricing models.

- Robot purchase price components include the mechanical arm itself, control systems, teaching pendants, and basic software packages. However, comprehending the true industrial robot cost requires looking beyond these elements. The majority of organisations discover that the complete cost of robotic automation exceeds initial robot purchases by substantial margins. Integration costs, system implementation expenses, and ongoing support fees constitute major portions of the total investment.

The total investment in robotic systems typically distributes as follows: robot hardware accounts for roughly 30-40% of expenses, while installation and integration consume 40-50%, with training, tooling, and contingencies representing the remaining 10-20%. This breakdown helps organisations budget more accurately and avoid unexpected expenditures during deployment phases.

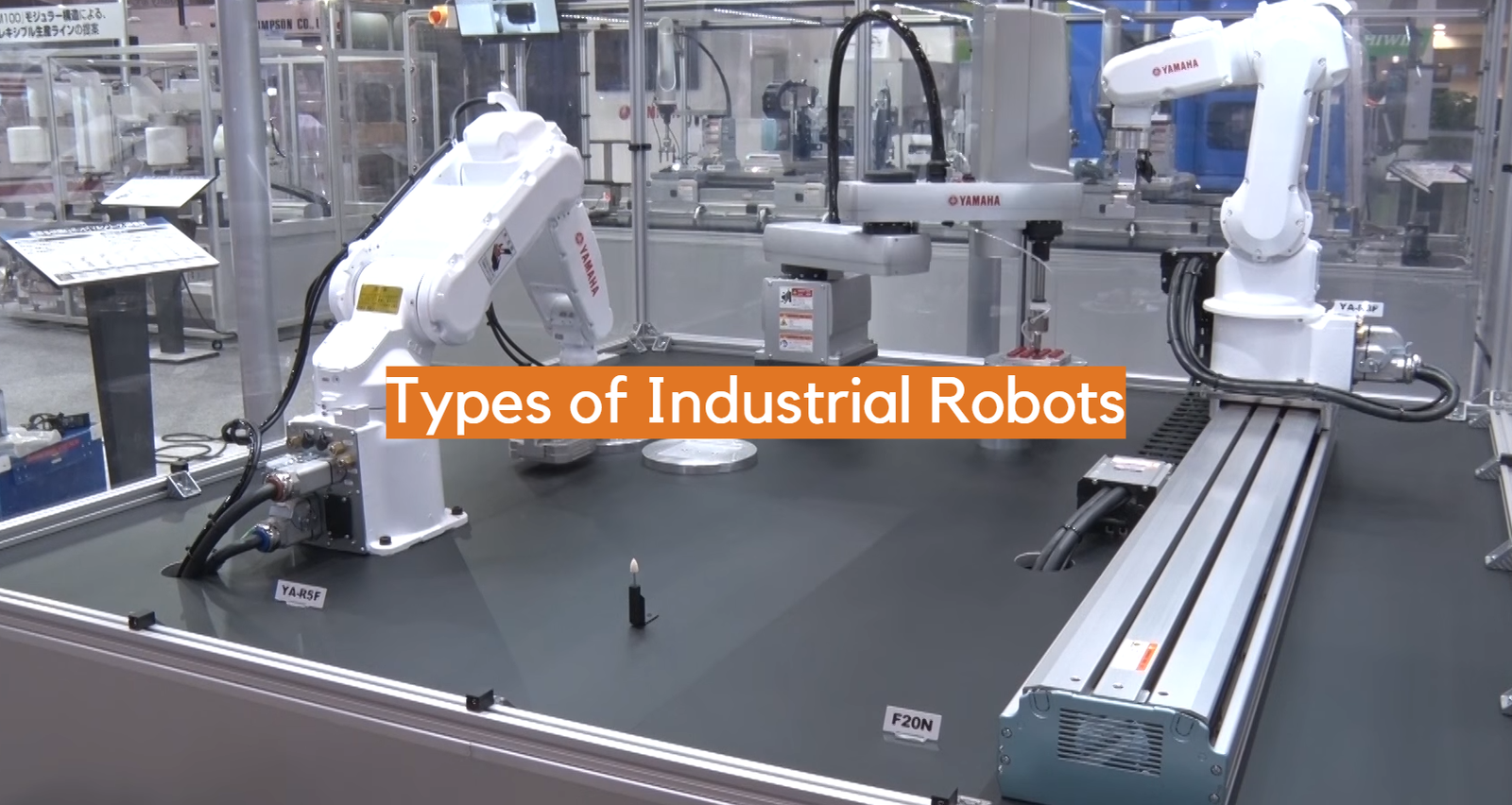

Types of Industrial Robots and Their Price Ranges

Collaborative Robots (Cobots): Affordable Automation Solutions

- Collaborative robot pricing has revolutionised the industrial robotics market by introducing cost-effective automation options for small and medium enterprises. Cobot costs begin at approximately $25,000 to $45,000 for basic models designed for light assembly, packaging, and machine tending applications.

- Entry-level collaborative robots offer flexibility without consuming excessive capital. These affordable cobots feature built-in safety systems, allowing human-robot collaboration without extensive safety fencing, significantly reducing installation costs. Mid-range cobots priced between $45,000 $75,000 incorporate enhanced payload capacity and software capabilities, accommodating moderately complex manufacturing tasks.

- Premium cobot systems exceed $90,000, particularly those equipped with advanced vision systems, specialised programming, and industry-specific configurations. The complete cobot system cost, including tooling, integration, and training, typically ranges from $40,000 to $150,000 for comprehensive deployments.

Traditional Articulated Robots: Heavy-Duty Industrial Solutions

- Articulated industrial robots represent the workhorses of manufacturing environments, handling demanding applications including welding, palletising, and material handling. Articulated robot pricing reflects their robust construction and advanced capabilities.

- Small articulated robots designed for confined spaces and light applications start around $25,000 to $50,000, making them suitable for precision assembly tasks and electronics manufacturing. Medium articulated robots handling diverse manufacturing operations range from $50,000 to $100,000, providing balanced capabilities for typical production requirements.

- Large industrial robots with substantial lift capacity and extended reach command prices between $100,000 $150,000 or higher. These heavy-duty systems perform tasks requiring significant force, extended workspace reach, and specialised precision. Welding robots, for instance, incorporate additional specialised controllers and safety systems, pushing welding robot costs toward the higher end of this spectrum.

Cartesian Robots: Specialised Linear Motion Systems

- Cartesian robot pricing demonstrates distinct characteristics from articulated systems. Small desktop Cartesian robots for educational purposes and light tasks cost $2,000 to $10,000, while industrial-grade Cartesian systems range from $20,000 to $100,000 or higher.

- Mid-range cartesian robots offering enhanced precision and speed capabilities typically cost between $30,000 $60,000. These systems excel in pick-and-place, assembly, and machine-tending applications where linear motion efficiency matters significantly. Complete Cartesian robot workcells with comprehensive tooling and integration can easily exceed $200,000 for high-end industrial implementations.

Key Cost-Driving Factors in Industrial Robot Pricing

Payload Capacity: The Primary Cost Driver

- Robot payload capacity stands as one of the most significant determinants of industrial robot cost. Payload refers to the maximum weight a robot can lift and manipulate safely while maintaining performance standards. Lightweight robots handling 5-10 kg payloads cost substantially less than those designed for 50 kg or higher loads.

- Heavy-payload robots requiring reinforced motors, stronger joint structures, and enhanced mechanical systems command premium pricing. A robot lifting 5 kg might cost $35,000, while comparable models handling 50 kg requirements can exceed $100,000. This payload-price correlation reflects fundamental engineering requirements and material specifications necessary for safe, reliable operation.

- End-of-arm tooling (EOAT) weight directly impacts effective payload capacity. A robot with a 20 kg nominal payload equipped with a 5 kg gripper effectively handles only 15 kg of workpieces. Organisations must accurately calculate total payload requirements, including tooling weight, when evaluating robot purchase decisions.

Reach and Precision Specifications

- Robot reach (working envelope) and precision tolerances significantly influence robot system pricing. Extended reach robots requiring longer arms and more robust support structures cost more than compact models with limited workspace. A robot reaching 1.5 meters costs considerably less than one achieving 3+ meter reach across multiple axes.

- High-precision robots capable of repeatability tolerances under 0.1mm command substantial price premiums over standard models with 0.5mm-1mm tolerances. Applications requiring tight tolerances—such as electronic assembly, medical device manufacturing, and precision machining—necessitate advanced components and sophisticated control systems, directly increasing total robot cost.

Number of Axes and Degrees of Freedom

Six-axis robots dominate modern manufacturing, offering maximum flexibility for complex manipulations. However, the number of axes directly correlates with robot pricing. Four-axis systems cost less than comparable six-axis configurations, while specialised SCARA robots (Selective Compliance Articulated Robot Arm) with four axes provide cost advantages for specific applications.

Each additional axis requires supplementary motors, controllers, and software complexity, incrementally raising robot system costs. Organisations should evaluate whether full six-axis capability justifies premium expenses compared to limited-axis systems better suited to specific manufacturing tasks.

Advanced Technology Integration

- Artificial intelligence capabilities, computer vision systems, and machine learning integration substantially increase robot costs. AI-equipped robots typically cost 20-40% more than comparable models lacking these features. Vision system integration alone can add $10,000 to $50,000 to base robot pricing.

- Advanced sensors, real-time optimisation algorithms, and cloud connectivity features represent emerging cost considerations. Organisations implementing Industry 4.0 solutions and IoT-enabled robotics must budget additional capital for these technological enhancements.

Installation, Integration, and System Implementation Costs

Integration and Commissioning Expenses

- Integration costs frequently exceed robot hardware expenses, yet organisations frequently underestimate this critical budget item. System integration services encompassing mechanical integration, electrical connections, safety certification, and control system calibration typically consume 30-50% of total project budgets.

- Integration complexity depends on existing facility infrastructure, production line compatibility, and customisation requirements. Straightforward installations integrating pre-engineered robot cells might cost $20,000-$50,000, while custom implementations adapting robots to unique production environments can exceed $150,000.

End-of-Arm Tooling and Peripherals

- Gripper costs, welding torch specifications, spray painting systems, and application-specific tooling represent substantial ancillary expenses. Standard grippers range from $5,000 to $20,000, while specialised end effectors for welding or precision handling can exceed $30,000. Custom EOAT designed specifically for unique manufacturing processes commands premium pricing.

- Safety systems, including fencing, light curtains, emergency stop mechanisms, and interlocking gates, add $10,000 to $40,000+, depending on complexity and regulatory requirements. Organisations must factor these essential safety components into comprehensive project budgeting.

Training and Operator Competency Development

- Employee training programs ensure safe, effective robot operation and maintenance. Operator training typically costs $2,000 to $10,000 per employee, while programmer certification courses can reach $15,000 or higher. Organisations deploying multiple robots across different production areas should budget $10,000 to $30,000+ for comprehensive training initiatives.

- Maintenance training for in-house technicians requires specialised knowledge in mechanical systems, electrical controls, and troubleshooting procedures. Extended support packages from manufacturers often include initial training but typically require additional investment for advanced technical development.

Total Cost of Ownership and Long-Term Financial Considerations

Maintenance and Support Costs

- Annual robot maintenance typically ranges from $3,000 to $6,000+ for preventive servicing, including parts replacement, recalibration, and routine inspections. Heavily-utilised robots operating multiple production shifts require more frequent maintenance, potentially doubling these costs in demanding environments.

- Preventive maintenance programs prove significantly more economical than reactive repair approaches. A minor breakdown might halt production for hours, incurring far greater costs than scheduled maintenance expenses. Manufacturers’ extended support agreements, often costing 10-15% of robot purchase price annually, provide peace-of-mind protection for critical production systems.

Payback Period and Return on Investment

- Robot payback periods typically range from 6 to 18 months, depending on application complexity and operational intensity. A $50,000 robot system replacing one shift worker generates approximately $40,000 to $60,000 in annual labour savings (including benefits and overhead). Additional benefits include reduced material waste, improved quality, increased throughput, and eliminated human error.

- ROI calculations should incorporate productivity gains (15-30% typical throughput improvements), quality enhancements (20-50% scrap reduction), and reduced downtime from human absences. Many organisations achieving payback within 18 months subsequently extend operations to multiple shifts, significantly amplifying financial returns throughout the robot’s 10-15 year operational lifespan.

Energy Consumption and Operational Expenses

Robot power consumption varies by system type, payload capacity, and operating cycle times. Most industrial robots consume 3-5 kilowatts during active operation, though larger systems might require higher power levels. Annual energy costs typically represent a small fraction (2-5%) of total ownership expenses.

Organisations can achieve energy efficiency gains through optimised motion programming, reduced cycle times, and strategic shift scheduling. Some manufacturers now offer energy-monitoring capabilities enabling real-time consumption tracking and optimisation.

Industry Specific Pricing Considerations

Welding Automation Solutions

- Welding robots command premium pricing due to specialised controllers, robust construction, and industry-specific safety systems. Arc welding robots typically range from $60,000 to $150,000+ for complete systems, including welding power sources and consumable management systems. Spot-welding robots often cost slightly less than arc-welding configurations.

- Integration costs for welding applications can actually exceed robot hardware expenses, as installations require specialised electrical infrastructure, gas delivery systems, and fume extraction equipment.

Pharmaceutical and Food Processing Applications

- Pharmaceutical manufacturing robots must comply with cGMP regulations (current Good Manufacturing Practice), adding substantial certification and validation expenses. Sterile handling requirements necessitate specialised cleanroom-compatible robotics, increasing total system costs by 25-50% compared to standard industrial applications.

- Food processing robots require stainless steel construction, enhanced cleanability, and specialised safety certifications for food-contact applications. These sector-specific requirements increase both hardware and integration expenses considerably.

Buying, Leasing, and Refurbished Robot Options

New Robot Purchases

- Buying new industrial robots remains the preferred option for organisations with stable workflows and long-term production commitments. New robot pricing reflects current manufacturing standards, latest technology integration, and comprehensive manufacturer support. Full warranties typically cover 12-24 months, and manufacturers provide certified technical support.

- Financing options for new purchases often feature favourable terms, with equipment financing at competitive rates enabling gradual payment distribution across operational periods.

Leasing and Rental Programs

- Robot leasing offers advantages for businesses uncertain about long-term automation requirements or experiencing fluctuating production demands. Monthly robot leasing costs typically represent 3-5% of the purchase price, spreading the total investment across operational periods. Leased systems often include maintenance, software updates, and technical support, reducing unexpected expenses.

- Short-term robot rentals ranging from days to months provide temporary automation solutions for seasonal demands, pilot projects, or production surges. Rental rates generally run 5-10% of monthly lease costs for short-term engagements.

Refurbished and Reconditioned Robots

Used industrial robots and refurbished systems offer substantial cost advantages, with reconditioned robots typically costing approximately 50% of comparable new systems. Refurbished industrial robots from reputable dealers include rebuilt components, updated electronics, and manufacturer recertification.

Organisations should carefully evaluate the refurbished robot’s condition, remaining expected lifespan, and warranty provisions before purchasing. Certified refurbished robots from authorised dealers provide reasonable risk mitigation compared to unknown private sales.

Also Read: Industrial Robotics Transforming Manufacturing and Production

Conclusion

The true cost of industrial robots extends significantly beyond initial hardware purchases, requiring a comprehensive evaluation of integration, training, maintenance, and operational considerations. Industrial robot pricing in 2025 reflects democratized automation technology, with costs declining while capabilities advance, creating unprecedented opportunities for organisations of all sizes to implement cost-effective automation solutions.

Entry-level collaborative robots starting at $25,000 alongside premium fully-integrated systems exceeding $500,000 demonstrate the extraordinary range available across diverse manufacturing requirements. By carefully assessing payload requirements, precision specifications, application complexity, and long-term financial projections, organisations can select appropriate robotic automation solutions delivering strong return on investment, typically achieving payback within 18 months while generating sustained competitive advantages through improved productivity, enhanced quality, and reduced operational costs throughout extended operational lifecycles.