Collaborative Robots vs Traditional Robots: What’s the Difference?

Discover the key differences between collaborative robots and traditional Traditional Robots. Learn about safety, cost, speed, and which is best.

The industrial automation landscape has undergone a significant transformation in recent decades, driven by technological innovations that have reshaped how manufacturing facilities operate. Among the most pivotal developments is the emergence of collaborative robots, commonly referred to as cobots, which represent a fundamental shift from traditional industrial robotics. While traditional robots have dominated factory floors for decades, executing high-speed, repetitive tasks with remarkable precision, collaborative robots introduce a new paradigm—one where human workers and robotic systems operate seamlessly in the same workspace.

The distinction between cobots and traditional robots is essential for manufacturers seeking to optimize their production processes, enhance workplace safety, and make informed investment decisions. This comprehensive guide explores the critical differences between these two robotic technologies, examining aspects such as safety mechanisms, programming capabilities, cost considerations, payload capacities, and ideal use cases. Whether you’re a manufacturing manager evaluating automation solutions, an operations professional planning facility upgrades, or an entrepreneur considering your first robotic investment, this article will equip you with the knowledge needed to determine which technology aligns best with your specific industrial requirements and long-term business objectives.

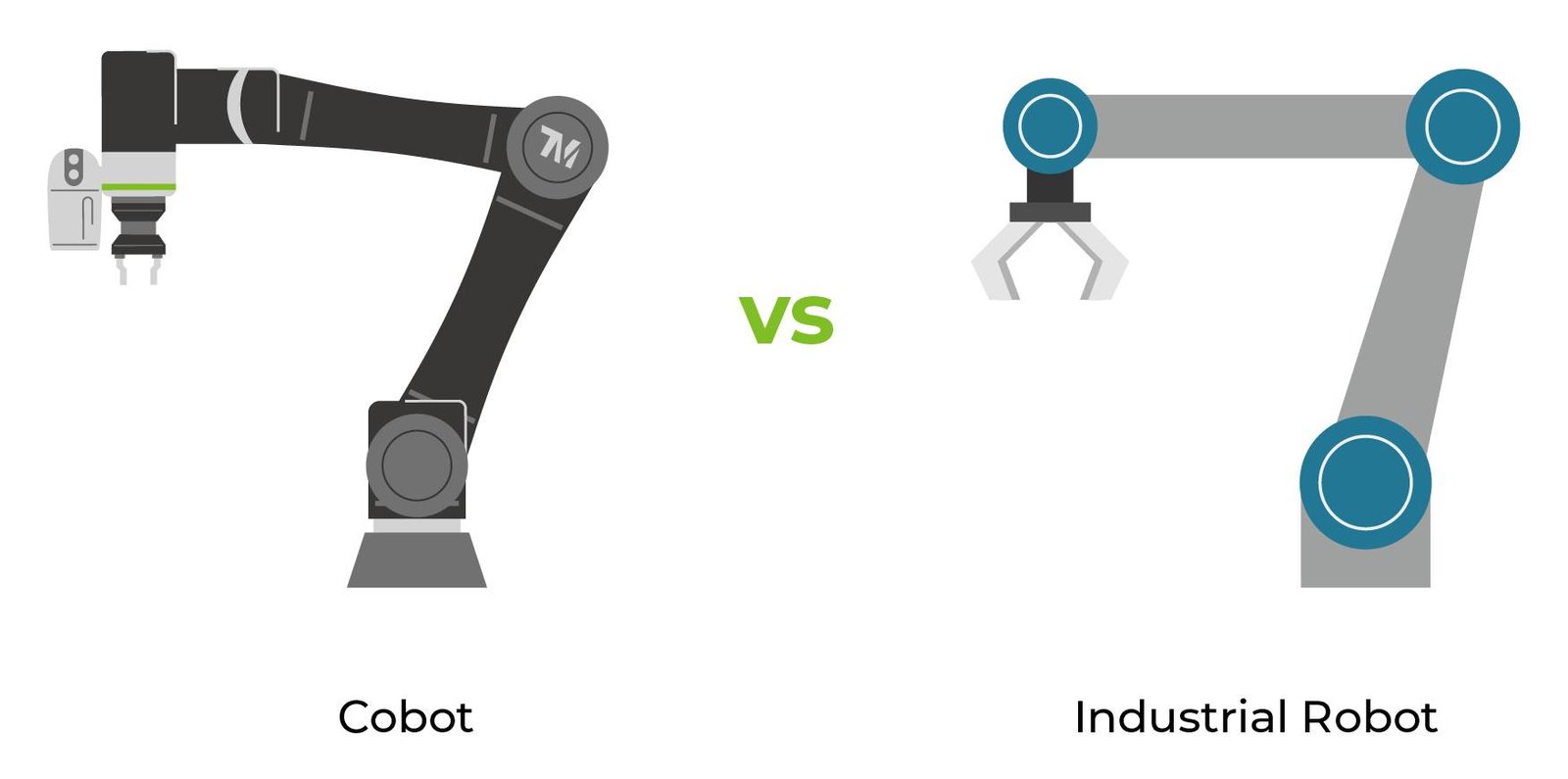

What Are Collaborative Robots?

Collaborative robots, also known as cobots, represent an innovative class of industrial automation equipment engineered specifically to operate safely alongside human workers. Unlike their traditional counterparts, cobots are designed with human interaction as a core principle, incorporating advanced sensors, force-limiting technology, and intelligent control systems that enable them to work in shared workspaces without the need for extensive protective barriers. The key characteristic that defines cobots is their inherent ability to detect human presence and respond appropriately by slowing down, stopping, or altering their operational parameters.

This fundamental design philosophy distinguishes cobots from traditional robots, which operate in isolated environments separated from human workers. Modern collaborative robotics has revolutionized automation accessibility, making sophisticated robotic systems available to small and medium-sized enterprises that previously could not justify the substantial investment required for traditional industrial robots. The cobot market has experienced explosive growth, with industry analysts projecting that collaborative robot installations will account for an increasingly significant share of all industrial robot deployments globally.

What Are Traditional Robots?

Traditional robots, also referred to as industrial robots or non-collaborative robots, are conventional robotic systems designed primarily for autonomous operation within dedicated, enclosed workspaces. These powerful machines excel at executing high-volume, repetitive manufacturing tasks with exceptional speed and precision. Traditional industrial robots operate independently, typically handling heavy payloads and performing complex movements at velocities that would be dangerous if humans were present in the immediate vicinity. Characterized by their substantial size, considerable weight, and impressive strength, traditional robots are optimized for scenarios where consistency, power, and throughput take precedence over flexibility.

These systems have been the backbone of industrial automation for decades, proving indispensable in automotive manufacturing, heavy equipment production, metal fabrication, and other demanding industrial applications. While traditional robots remain unmatched in their ability to handle intensive, standardized production runs, they require significant infrastructure investment, including safety cages, extensive programming expertise, and substantial floor space allocation, making them less suitable for smaller operations or applications with variable production requirements.

Key Differences Between Collaborative Robots and Traditional Robots

1. Safety Features and Workplace Integration

One of the most striking differences between collaborative robots and traditional robots lies in their safety architecture and workplace integration capabilities. Collaborative robots are engineered with multiple layers of built-in safety mechanisms that enable them to operate safely in proximity to human workers. These safety systems include force and torque limiting sensors, collision detection technology, reduced speed modes, and real-time monitoring systems that allow cobots to respond instantaneously to unexpected human contact. Cobots comply with international safety standards, including ISO/TS 15066 and ISO 10218, which establish specific guidelines for safe human-robot interaction.

Conversely, traditional robots are designed under the assumption of complete physical separation from human operators. Because traditional industrial robots operate at higher speeds and with greater force, they require protective cages, light curtains, safety mats, and emergency stop systems to prevent workplace injuries. The installation of these safety infrastructure components significantly increases the total cost of traditional robot deployment and consumes valuable factory floor space. Cobots, by contrast, typically operate without dedicated safety cages, allowing manufacturers to deploy them directly into existing production areas with minimal environmental modifications.

2. Programming and Ease of Use

The accessibility and user-friendliness of collaborative robots represent another fundamental distinction from traditional robots. Cobots feature intuitive programming interfaces that enable non-specialist personnel to configure and reconfigure them for different tasks without requiring advanced robotics expertise. Many cobot manufacturers have implemented hand-guiding or lead-through-teach methodologies, where operators physically guide the robot through desired movements, and the collaborative robot learns and memorizes these motions for future execution. This teaching method democratizes automation, allowing production workers, technicians, and supervisors to participate in robot programming and task customization.

In stark contrast, traditional robots demand sophisticated programming knowledge, typically requiring specialized robotics engineers to write complex code and manage system parameters. Programming traditional robots involves intricate software interfaces, often necessitating the expertise of professional automation integrators. Consequently, modifying traditional robot tasks or repurposing them for new applications can consume weeks or months of engineering time and substantial financial resources, whereas cobot reprogramming typically requires only hours of operator training and hands-on practice.

3. Speed and Performance

A notable trade-off exists between the speed capabilities of collaborative robots and traditional robots. Traditional industrial robots are optimized for maximum velocity, capable of executing movements exceeding 1 meter per second, making them ideal for high-volume production environments where throughput is paramount. These traditional robots can complete complex assembly, welding, painting, and palletizing operations at speeds that dramatically exceed human capability, processing thousands of units per shift with consistent precision. Collaborative robots, conversely, operate at considerably slower speeds, typically ranging from 250 to 500 millimeters per second, due to their integrated safety constraints.

This reduced speed is a deliberate design choice that ensures that even if a cobot makes contact with a human worker, the impact force remains within safe limits that cannot cause serious injury. For applications requiring extremely rapid production cycles or high-speed material handling, traditional robots remain the superior choice. However, for many manufacturing scenarios involving assembly, packaging, light material handling, and quality inspection, the speed differential between cobots and traditional robots is negligible relative to the overall productivity gains achieved through improved flexibility and reduced downtime for configuration changes.

4. Payload Capacity and Strength

The payload capacity and strength characteristics of collaborative robots differ substantially from traditional robots. Cobots typically handle payloads ranging from 3 to 10 kilograms, though some advanced collaborative robot models can accommodate loads up to 35 kilograms. This payload limitation reflects cobot design priorities, which emphasize safety, portability, and human-robot collaboration over brute strength. The lightweight construction of cobots makes them easy to relocate, reconfigure, and integrate into different workstations without requiring permanent structural modifications.

Traditional industrial robots, by contrast, are engineered to manipulate substantially heavier loads, with many models capable of handling payloads exceeding 500 kilograms, and heavy-duty variants managing loads up to 2 tons or more. This extraordinary strength makes traditional robots indispensable for applications involving large automotive components, heavy metal fabrication, bulk material handling, and other demanding industrial processes. For manufacturers whose primary requirements involve manipulating heavy materials or large assemblies, traditional robots represent the only viable automation solution, as the payload limitations of cobots would render them unable to perform essential manufacturing tasks.

5. Cost Considerations

Cost represents a critical factor in the decision between collaborative robots and traditional robots. Collaborative robots generally feature lower acquisition costs compared to traditional robots, typically ranging from $35,000 to $150,000 per unit, depending on specifications and capabilities. Beyond the robot purchase price, cobot deployment involves minimal additional infrastructure costs, as they do not require safety cages, extensive electrical infrastructure modifications, or specialized facility redesign. The total cost of ownership for cobots remains favorable due to reduced installation complexity, minimal training requirements, and the absence of expensive safety apparatus.

Traditional robots, conversely, involve substantially higher capital investment, often ranging from $100,000 to $500,000 per unit for advanced industrial systems. Beyond the robot itself, organizations must allocate significant budget for safety cage construction, electrical and pneumatic system installation, comprehensive programming services, specialized operator training, and potential facility renovations.

When considering the complete investment picture—including infrastructure, professional services, training, and integration costs—traditional robots typically demand three to five times the total investment required for comparable cobot solutions. This significant cost differential has democratized industrial automation, enabling small and medium-sized manufacturers to access sophisticated robotic capabilities previously available only to large corporations with substantial capital budgets.

6. Flexibility and Task Versatility

Collaborative robots excel in environments requiring task flexibility and rapid process modifications, while traditional robots are optimized for long-term, standardized production runs. Cobots can be quickly reprogrammed or reconfigured to perform entirely different tasks, making them ideal for manufacturers operating in high-mix, low-volume production environments where product specifications frequently change. A single cobot can transition from performing assembly tasks to packaging, labeling, or quality inspection operations with minimal downtime and no requirement for engineering intervention.

This flexibility transforms cobots into valuable assets that can be deployed across multiple production lines and workstations, maximizing equipment utilization rates. Traditional robots, designed for specific, high-volume applications, are far less flexible. Repurposing a traditional robot for a different task typically requires substantial end-of-arm tooling modifications, complete programming overhauls, and potentially significant mechanical reconfiguration.

Consequently, traditional robots are most economically justified in scenarios where production requirements remain consistent over extended periods, allowing the organization to amortize the substantial setup investment across thousands or hundreds of thousands of units. For organizations confronting volatile market demands, frequent product modifications, or the need for rapid production line reconfigurations, collaborative robots provide superior operational adaptability.

7. Space and Facility Requirements

The spatial requirements of collaborative robots and traditional robots differ substantially, with significant implications for facility layout and utilization. Collaborative robots feature compact designs that allow them to be positioned directly on standard workbenches, integrated into existing production stations, or mounted on mobile platforms without requiring dedicated floor space or facility modifications. Because cobots do not require protective cages or safety barriers, manufacturers can optimize facility layouts, eliminate bulky safety infrastructure, and deploy robots in tight production environments where space is premium.

This spatial efficiency has particular value in facilities with constrained floor space or crowded production areas. Traditional robots, in contrast, demand substantial dedicated workspace to accommodate their physical size and to provide the mandatory safety barriers, lighting systems, and emergency egress routes. The installation of traditional robot safety cages, light curtains, and warning systems consumes significant floor area, often requiring permanent facility modifications and layout redesigns.

For manufacturers operating in space-constrained environments or facilities with limited expansion capacity, the substantial spatial demands of traditional robots may render them impractical, regardless of their operational capabilities, making cobots the only feasible automation solution.

Advantages and Disadvantages

Advantages of Collaborative Robots

Collaborative robots offer compelling advantages that have driven their rapid market adoption. Enhanced workplace safety represents the foremost benefit, as cobot force-limiting technology and collision detection systems substantially reduce injury risk compared to working with traditional robots. The accessibility of cobot programming enables distributed expertise throughout the organization, eliminating dependence on specialized robotics engineers for implementation and modification.

The lower total cost of ownership, combined with rapid deployment capabilities, allows organizations to achieve positive return-on-investment within months rather than years. Additionally, cobots support incremental automation strategies, enabling organizations to introduce robotic systems gradually, assess productivity gains, and expand automation methodically without massive upfront capital commitments. The flexibility and ease of task reconfiguration make cobots particularly valuable in dynamic manufacturing environments. Finally, cobots support human worker retention by handling tedious, repetitive, or hazardous tasks, allowing human employees to focus on higher-value activities requiring creativity, judgment, and problem-solving capabilities.

Disadvantages of Collaborative Robots

Despite their numerous advantages, cobots present certain limitations. The lower payload capacity restricts applicability for heavy material handling or large component manipulation. Speed limitations, while acceptable for many applications, preclude cobots from high-speed, high-volume production environments requiring extreme throughput.

The requirement for comprehensive risk assessments and potential safety certification requirements when tasks or end-of-arm tooling change adds administrative complexity and potential costs. Collaborative robots typically lack the precision level of high-end traditional robots, making them unsuitable for ultra-precision manufacturing processes. Finally, while cobots can theoretically operate continuously, practical constraints related to human worker shifts, maintenance scheduling, and changeover requirements limit their 24/7 operational advantage compared to fully autonomous traditional robots.

Advantages of Traditional Robots

- Traditional robots maintain compelling advantages for specific applications. Their exceptional speed and throughput capacity make them indispensable for high-volume production environments where rapid cycle times drive profitability. The high payload capacity enables the manipulation of heavy materials and large components impossible for collaborative robots.

- Traditional robots deliver exceptional precision and consistency, essential for applications where microscopic tolerances or flawless repeatability determine product quality. Their capacity for completely autonomous operation without human supervision or assistance allows 24/7 production with minimal labor requirements. For applications where these characteristics align with operational requirements, traditional robots remain unmatched in delivering maximum productivity and output volume.

Disadvantages of Traditional Robots

Traditional robots face substantial disadvantages compared to cobots. The massive capital investment required for purchase, installation, safety infrastructure, and professional services creates substantial financial barriers. The extensive programming expertise required and the complexity of task modifications make traditional robots costly and time-consuming to repurpose.

The large footprint and space requirements, combined with mandatory safety caging and infrastructure, limit facility layout flexibility. The skills requirement for programming and maintenance creates organizational dependency on specialized expertise. Finally, the substantial setup time and capital commitment make traditional robots economically irrational for small manufacturers or organizations with variable production requirements.

Which Should You Choose?

Choose Collaborative Robots If:

Select collaborative robots for your manufacturing facility if your operation emphasizes flexibility, requires rapid product changeovers, operates with a limited capital budget, needs to introduce automation gradually, demands close human-robot collaboration, encounters space constraints, or prioritizes workplace safety enhancement. Cobots prove ideal for small to medium-sized manufacturers, facilities producing multiple product variants, businesses experiencing fluctuating production volumes, and organizations seeking to augment human worker capabilities rather than replace them entirely.

Choose Traditional Robots If:

Opt for traditional robots when your manufacturing process involves standardized, high-volume production, requires handling of heavy materials or large components, demands maximum speed and throughput, benefits from 24/7 autonomous operation, requires ultra-high precision, involves hazardous materials or extreme environmental conditions, or necessitates long-term amortization of capital investment over consistent production runs. Traditional robots suit large-scale manufacturers, automotive suppliers, heavy equipment manufacturers, and facilities producing standardized commodity products with minimal variation.

Industrial Applications and Use Cases

Collaborative Robot Applications

Collaborative robots excel in assembly operations, small parts handling, machine tending, quality inspection, packaging and labeling, electronics assembly, laboratory automation, food and beverage processing, material handling in confined spaces, and collaborative pick-and-place operations. Companies across healthcare, pharmaceutical manufacturing, electronics, small appliance production, and artisanal manufacturing sectors have successfully deployed cobots to enhance productivity while maintaining workforce stability.

Traditional Robot Applications

Traditional robots dominate automotive manufacturing, heavy equipment fabrication, metal stamping and welding, high-speed packaging, bulk material handling, hazardous material processing, large-scale assembly, heavy component manipulation, and ultra-precision applications. These industrial robots remain essential in industries requiring extreme speed, power, or precision that cobots cannot deliver.

Future Trends in Robotics

The robotics industry continues evolving, with advancing technology blurring traditional distinctions between collaborative robots and traditional robots. Safety-rated external sensing systems enable traditional robots to operate faster while maintaining collaborative safety standards. Conversely, cobot manufacturers continuously enhance speed, payload capacity, and precision to address more demanding applications. Artificial intelligence and machine learning integration into both cobot and traditional robot systems promises improved autonomy, adaptability, and predictive maintenance capabilities. The emerging field of hybrid robotics combines elements of both collaborative and traditional systems, offering organizations flexibility in optimization based on specific application requirements.

Also Read: Social Robots Building Emotional Connections with Machines

Conclusion

The choice between collaborative robots and traditional robots represents a strategic decision requiring careful analysis of your specific manufacturing requirements, operational constraints, and long-term business objectives. Collaborative robots have democratized industrial automation, making sophisticated robotic systems accessible to organizations of all sizes, while traditional robots remain superior for high-volume, high-speed, heavy-duty applications requiring maximum throughput and precision.

Cobots excel in dynamic, flexible environments where task variety and rapid changeover matter, while traditional robots deliver unmatched performance in standardized production scenarios. Your selection should reflect an honest assessment of your production volume, payload requirements, speed demands, available capital budget, facility constraints, workforce capabilities, and growth trajectory.

Many large manufacturers optimize by deploying both collaborative robots and traditional robots strategically across different production lines, leveraging each technology’s unique strengths. As robotics technology continues advancing and safety standards evolve, the distinction between these technologies will continue narrowing, offering organizations even greater flexibility in automating their manufacturing processes efficiently and safely.