How IoT Is Actually Used in Manufacturing

Discover how IoT transforms manufacturing with predictive maintenance, smart factories, real-time monitoring, and Industry 4.0 solutions that boost.

The manufacturing industry stands at a technological crossroads where Internet of Things (IoT) technology is fundamentally reshaping how factories operate, machines communicate, and decisions get made. While many business leaders hear about IoT in manufacturing as a futuristic concept, the reality is that industrial IoT has already moved beyond theoretical promise into practical, revenue-generating implementation across thousands of facilities worldwide. The difference between theoretical IoT manufacturing and real-world deployment often lies in concrete applications—not just sensors hanging from machinery, but integrated ecosystems generating measurable business value.

The global IoT in manufacturing market size is expected to grow from USD 33.2 billion in 2020 to USD 53.8 billion in 2025 at a compound annual growth rate of 10.1 percent, signaling genuine industry transformation rather than a passing technology trend. What distinguishes successful IoT implementation from failed initiatives is grasping how smart factories leverage interconnected devices to solve genuine operational challenges. A smart factory doesn’t require replacing entire production lines with cutting-edge equipment; instead, it strategically deploys IoT sensors to collect real-time data about existing equipment health, production efficiency, and environmental conditions.

Companies implementing digital twins alongside IoT technology—such as Unilever—report annual savings of $2.8 million due to reduced energy consumption and increased productivity, demonstrating concrete financial returns. The convergence of Industry 4.0 technologies—combining predictive maintenance, real-time monitoring, and data analytics—creates competitive advantages for manufacturers willing to embrace digital transformation. This comprehensive guide explores actual IoT manufacturing applications, moves beyond marketing hype, and reveals how progressive manufacturers deploy IoT solutions to achieve measurable improvements in equipment reliability, production quality, worker safety, and operational costs.

IoT and Its Role in Manufacturing

- Internet of Things (IoT) fundamentally refers to networks of physical devices, machines, and sensors embedded with connectivity, allowing them to collect, exchange, and analyze data without human intervention. In manufacturing contexts, this means factory equipment becomes “smart”—capable of communicating its operational status, detecting anomalies, and triggering responses automatically. The distinction between traditional manufacturing and IoT-enabled manufacturing centers on data visibility and responsiveness. Legacy factories operate with limited visibility into equipment health, discovering problems through breakdowns and visual inspection. Smart factories, by contrast, achieve continuous monitoring of thousands of parameters simultaneously through networked sensors.

- Industrial IoT (IIoT) encompasses specialized IoT applications optimized for industrial environments’ demanding conditions. Unlike consumer IoT devices requiring occasional charging and operating in stable environments, IIoT systems must withstand temperature extremes, vibration, dust, and corrosive atmospheres while maintaining reliable connectivity. In manufacturing, IIoT applications include barcode scanners, web cameras, signal lights, and sensors measuring temperature, humidity, and vibration, creating interconnected networks where machines share performance data continuously. This shift from isolated equipment to networked systems represents the foundation enabling Industry 4.0—the fourth industrial revolution characterized by advanced automation, real-time monitoring, and intelligent decision-making.

Predictive Maintenance: The Primary IoT Application in Manufacturing

- Predictive maintenance represents perhaps the most impactful IoT manufacturing application, transforming maintenance from reactive (fixing broken equipment) to proactive (preventing failures before they occur). Traditional maintenance operates on fixed schedules—replacing parts every twelve months regardless of actual condition or remaining lifespan. This approach wastes resources through unnecessary component replacement while not protecting against premature failures occurring between scheduled intervals.

- IoT-based predictive maintenance inverts this logic entirely. Predictive maintenance uses IoT sensors to continuously monitor the health of machinery, collect real-time data, and apply advanced analytics to forecast potential issues. Sensors embedded directly on equipment track critical parameters—vibration signatures, temperature fluctuations, acoustic emissions, and electrical consumption patterns—transmitting this data to cloud-based analytics platforms. Machine learning algorithms analyze these data streams, establishing baseline operational patterns and identifying subtle deviations signaling potential component degradation.

Consider a manufacturing facility operating hundreds of electric motors. Traditional preventive maintenance schedules motor replacement every 50,000 operating hours regardless of actual condition. Some motors fail prematurely due to dust accumulation or bearing wear; others run reliably for 80,000 hours without intervention. By deploying IoT sensors that monitor vibration and temperature, facility managers gain precise equipment health insights.

When a motor’s vibration signature indicates accelerating bearing wear, predictive algorithms alert maintenance teams with sufficient warning to schedule replacement during planned downtime rather than responding to catastrophic failure. This approach simultaneously reduces unnecessary replacement costs and eliminates unexpected production interruptions.

Real-Time Monitoring and Production Optimization

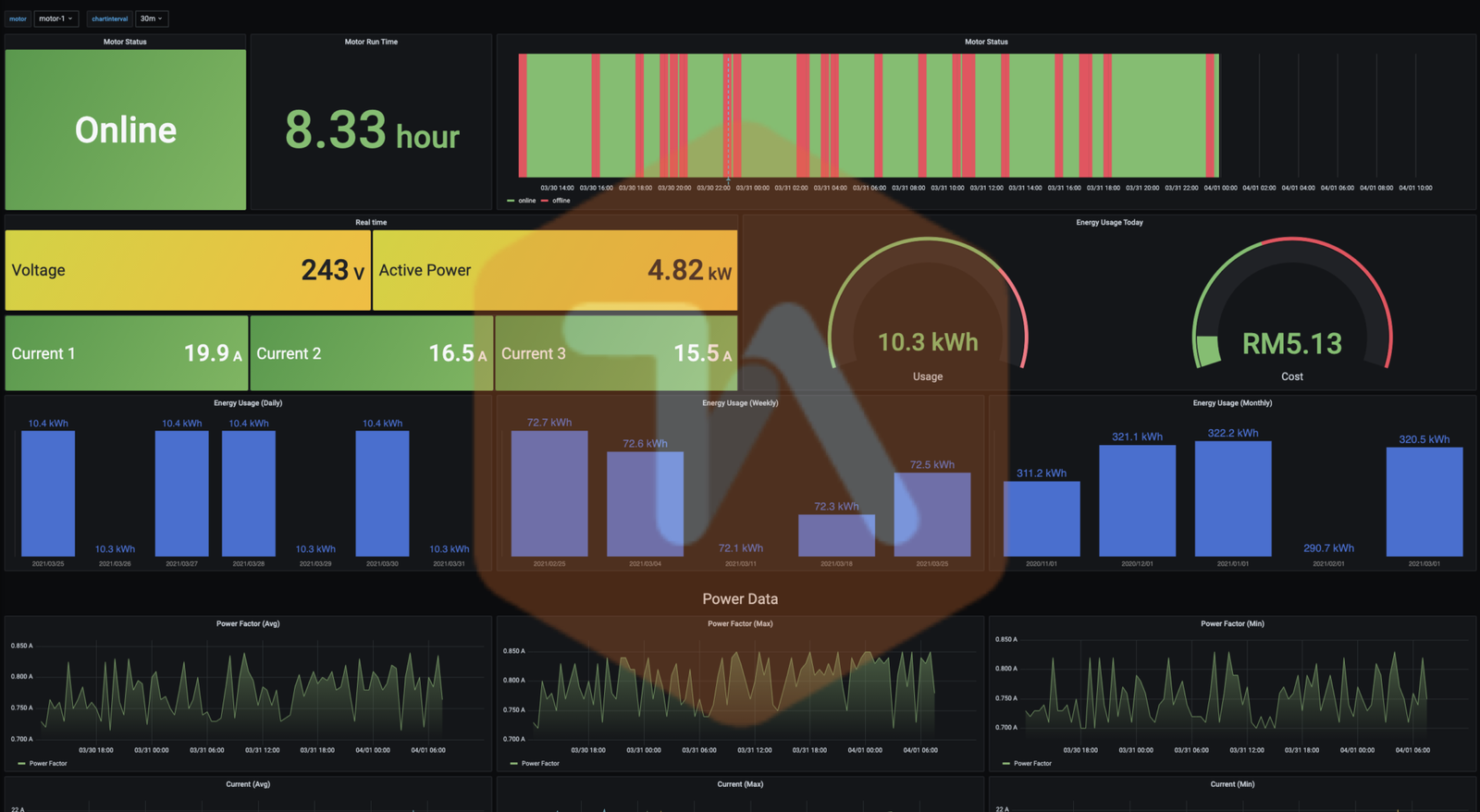

- Real-time monitoring powered by IoT sensors provides manufacturing leadership with unprecedented visibility into production floor operations. Rather than discovering production issues hours or days after they occur—when reviewing batch quality reports or investigating customer complaints—managers now access live dashboards displaying equipment status, production metrics, and environmental conditions as events unfold.

- Manufacturing dashboards aggregate data from hundreds of connected machines into intuitive visual interfaces. Production managers observe which assembly lines are operating at peak efficiency, which machines are approaching maintenance thresholds, and which processes are generating quality anomalies. This visibility enables rapid intervention: if temperature monitoring detects a cooling system malfunction affecting product quality, supervisors can halt production and deploy maintenance teams immediately rather than discovering defective products after production completion.

Connected equipment via machine monitoring solutions provides manufacturing leaders, plant managers, and operators with insight into all machines with visual manufacturing dashboards tracking performance against production goals, enabling optimization of process performance, predictive maintenance scheduling, and quality assurance protocols.

Process optimization accelerates dramatically when manufacturers understand actual equipment capabilities through data rather than relying on manufacturer specifications or historical assumptions. An injection molding machine’s cycle time might technically achieve sixty-second intervals per manufacturer specifications, but real-world variables—material temperature variations, humidity effects on polymer properties, mold degradation—might necessitate ninety-second cycles for consistent quality. IoT-enabled monitoring reveals these real-world constraints, permitting managers to optimize parameters within actual capabilities rather than theoretical limits.

Quality Control and Defect Detection

- Quality control represents a critical manufacturing function where IoT technology delivers substantial improvements. Traditional quality assurance relies on statistical sampling—producing batches, inspecting samples, and inferring batch quality from limited data. This approach risks shipping defective products and wasting production capacity on defective units before detection.

- IoT-based quality control shifts toward continuous monitoring of production parameters throughout manufacturing processes. Rather than inspecting final products, manufacturers now monitor conditions determining product quality in real-time. Temperature sensors ensure components are processed at the exact specifications. Pressure monitors confirm hydraulic systems maintain required tolerances. Humidity sensors verify that environmental conditions align with material requirements. When any parameter drifts beyond acceptable ranges, the system immediately alerts operators and halts production before defects occur.

IoT sensors monitor the production process and detect defects in real-time, allowing manufacturers to make adjustments before defective products are produced. This proactive approach dramatically reduces scrap rates—the percentage of produced units requiring rework or rejection—directly improving profitability. For high-volume manufacturing where scrap costs accumulate rapidly, reducing defect rates from 2% to 0.5% represents millions in annual savings while simultaneously improving customer satisfaction through superior product consistency.

Asset Tracking and Inventory Management

- Asset tracking using IoT sensors transforms inventory management from periodic manual counting to continuous visibility. Manufacturing facilities often contain thousands of components scattered across warehouses, assembly areas, work-in-progress storage, and shipping zones. Lost or misplaced inventory requires duplicate ordering, creates production delays, and artificially inflates apparent inventory costs.

- IoT-enabled asset tracking embeds location beacons into high-value components, tools, and raw materials. Managers access real-time location data through facility dashboards, eliminating tedious manual inventory counts and immediately locating specific components when needed. Maintenance teams equipped with mobile devices can instantly locate required tools rather than searching storage areas. Production planners know exact component locations and availability without waiting for inventory spreadsheets. This visibility enables just-in-time manufacturing—ordering components precisely when needed rather than maintaining large safety stock buffers—reducing working capital requirements and storage costs.

Worker Safety Enhancement Through IoT

- Worker safety represents another compelling IoT manufacturing application. Manufacturing environments present inherent hazards—heavy machinery, hazardous chemicals, high temperatures, loud noise levels, and confined spaces. Preventing accidents requires constant vigilance, often exceeding human capability, particularly during extended shifts when attention naturally wanes.

- IoT-enabled safety systems create continuous monitoring, extending protective capability far beyond occasional human supervision. Environmental sensors detect hazardous chemical concentrations, alerting workers to ventilation problems before exposure becomes dangerous. Temperature monitors identify localized heat hazards that might be invisible to workers. Wearable IoT devices—smart watches, proximity badges, protective headgear with embedded sensors—continuously track worker location and vital signs.

If a worker enters a confined space, the system confirms proper ventilation before access. If a worker’s stress levels indicate fatigue or heat stress, the system alerts supervisors, suggesting breaks. In emergencies, IoT systems immediately locate affected workers and alert rescue teams to specific locations rather than requiring verbal communication.

Energy Efficiency and Cost Reduction

- Energy consumption represents one of manufacturing’s largest operational expenses. Many facilities operated for decades without comprehensive energy monitoring, treating electricity as an undifferentiated utility cost impossible to reduce. IoT-based energy management dramatically changes this reality by measuring energy consumption at the granular equipment level.

- Smart energy sensors monitor power consumption for each machine, production line, or facility area. Facility managers discover which equipment operates inefficiently, consuming disproportionate energy relative to output. An aging compressor might consume 30% more electricity than modern alternatives, justifying replacement investment.

Equipment left running during non-production hours wastes substantial energy. Armal, a manufacturer of portable toilets, monitored IoT sensors during the production process, helping reduce the energy costs of machinery by almost 40 percent, demonstrating significant cost reduction potential. IoT energy management also optimizes production scheduling—running energy-intensive processes during off-peak hours reduces electricity costs where utility rates vary throughout the day.

Digital Twins and Advanced Simulation

Digital twin technology represents an advanced IoT manufacturing application combining sensor data with three-dimensional virtual models of physical equipment. A digital twin is a living virtual copy of physical machinery constantly synchronized with real-time sensor data. Engineers can run simulations within the digital environment—testing parameter adjustments, exploring optimization opportunities, or troubleshooting problems—without affecting actual production equipment.

Unilever uses digital twins to assess production time—how long it takes to produce a bottle of shampoo, helping engineers optimize the manufacturing process, and also to control moisture levels in soap-making machines, enabling consistent product quality. The ability to test changes virtually before physical implementation dramatically reduces the risk associated with manufacturing modifications. Engineers understand the consequences of adjustments, identify optimal parameters, and verify solutions work before modifying actual equipment. This capability accelerates innovation while minimizing disruption to production.

Integration with Industry 4.0 and Smart Factory Concepts

Industry 4.0, the fourth industrial revolution, represents the convergence of digital manufacturing technologies, including IoT, artificial intelligence, cloud computing, and edge processing into integrated ecosystems. Smart factories implementing Industry 4.0 principles don’t merely add sensors to existing equipment; they architect comprehensive systems where data flows seamlessly between machines, analytics platforms, and human decision-makers.

A smart factory operating under Industry 4.0 principles exhibits characteristics distinguishing it from traditional facilities. Production systems adapt automatically to demand changes without human intervention. Equipment schedules its own maintenance before failures occur. Quality control happens continuously during production rather than after. Supply chain visibility extends from component suppliers through distribution to end customers. Worker productivity increases through smart tools providing real-time guidance and reducing time searching for information or resources.

92% of industrial companies are executing digital transformation initiatives with goals of achieving improvements through Industry 4.0 technologies, reflecting widespread recognition that competitive advantage increasingly depends on digital capabilities. The manufacturers leading their industries aren’t necessarily those with the newest equipment, but rather those harnessing data from existing infrastructure through strategic IoT implementation.

Overcoming Implementation Challenges

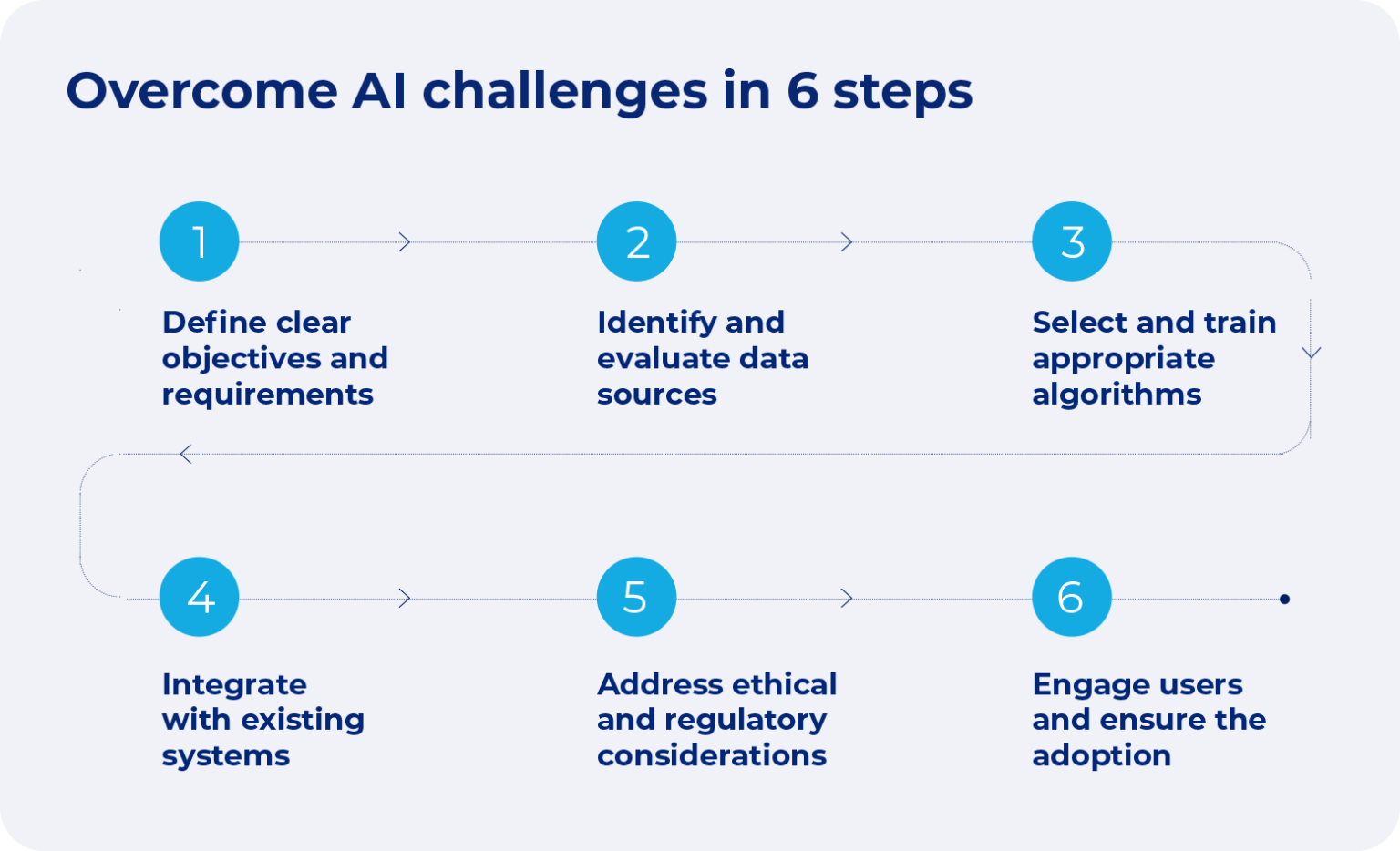

Despite compelling benefits, IoT implementation in manufacturing faces genuine obstacles requiring strategic attention. Legacy manufacturing facilities often contain equipment manufactured decades ago, before connectivity was even contemplated. These machines lack native network interfaces, requiring retrofit sensors and gateways to enable participation in IoT ecosystems. While technically feasible, retrofitting thousands of machines involves substantial capital investment alongside complexity in coordinating changes across active production environments.

Cybersecurity presents critical concerns. Manufacturing facilities increasingly operate in interconnected environments where equipment connects to corporate networks, cloud platforms, and sometimes even external partners’ systems. Each connection point represents a potential vulnerability where unauthorized access could disrupt production, compromise product quality, or expose proprietary manufacturing information. Securing industrial IoT networks requires specialized expertise beyond traditional IT security, involving industrial control system security and equipment-level protections.

Data management complexity grows exponentially with IoT scale. A facility with 500 connected machines might generate hundreds of terabytes of sensor data annually. Storing, processing, and analyzing such volumes requires sophisticated infrastructure and expertise. Many manufacturers lack in-house capabilities for industrial IoT analytics, creating dependency on specialized consultants or cloud service providers.

Organizational resistance often represents the most underestimated implementation challenge. Manufacturing operations value stability and proven processes. IoT transformation requires changing how engineers approach problems, how supervisors manage production, and how leadership evaluates performance. Staff trained in traditional manufacturing sometimes view digital transformation as threatening job security rather than tools enhancing their capabilities. Successful implementations involve extensive change management addressing these human factors alongside technical deployment.

Real-World Success Examples and ROI

Concrete examples demonstrate that IoT manufacturing benefits aren’t theoretical future possibilities but a tangible current reality. The Volkswagen Group recently developed the Volkswagen Industrial Cloud in collaboration with Amazon Web Services (AWS) to modernize its automotive manufacturing and logistics processes, with the potential to elevate productivity by 30 percent, reduce factory costs by 30 percent, and save €1 billion in supply chain expenses. Such results reflect genuine returns achievable through strategic IoT implementation.

DeWalt, the power tool manufacturer, deployed IoT solutions across manufacturing facilities and product lines. Smart factory initiatives in Mexico increased production of woodworking routers by 24% while reducing operational costs. The company extended IoT capabilities into products themselves—connected batteries monitoring charge levels and transmitting usage data, enabling predictive maintenance recommendations and theft prevention through automated shutdowns.

Caterpillar’s implementation showcases IoT’s value in heavy equipment manufacturing. Connected sensors on construction machinery transmit health data to remote monitoring centers, where analytics predict maintenance needs and schedule service accordingly. Augmented reality applications guide maintenance technicians through repair procedures, reducing repair times and improving first-time success rates. Marine asset intelligence divisions use sensor analytics to optimize vessel scheduling and fuel consumption patterns, saving substantial costs on shipping operations.

Future Trends and Emerging Technologies

- IoT manufacturing continues evolving rapidly as complementary technologies mature. 5G connectivity promises dramatic speed improvement, enabling real-time processing currently impossible with existing network capabilities. Edge computing shifts data processing from distant cloud servers to local devices, enabling faster response times and reduced network dependency—critical for manufacturing environments requiring instantaneous reactions.

- Artificial intelligence integration transforms IoT analytics from reporting what happened into predicting what will happen and recommending optimal responses. Machine learning algorithms are increasingly autonomous in identifying patterns, optimizing operations, and making decisions without human involvement. Blockchain technology addresses supply chain transparency and security concerns, enabling tamper-proof records of manufacturing conditions and component origins.

Also Read: Industrial IoT Transforming Manufacturing with Connected Systems

Conclusion

IoT in manufacturing has transitioned from an emerging technology concept to an operational reality, with thousands of facilities worldwide implementing IoT solutions, generating measurable financial returns through predictive maintenance, real-time monitoring, quality control improvements, and operational optimization. 58% of manufacturers say IoT is required to transform industrial operations digitally, reflecting widespread industry consensus about technology importance.

Successful implementations recognize that IoT technology itself isn’t the objective—rather, it’s a tool enabling better decisions, faster response times, and continuous improvement. Manufacturers beginning their IoT journey should focus initially on the highest-impact applications, such as predictive maintenance and real-time production monitoring, where data directly improves profitability, rather than attempting a comprehensive facility transformation overnight. As smart factory capabilities mature and complementary technologies like 5G, AI, and edge computing proliferate, competitive advantages flowing from IoT adoption will only intensify, making digital transformation increasingly non-negotiable for manufacturers pursuing long-term success.