The manufacturing landscape is experiencing an unprecedented transformation driven by Industrial IoT (IIoT) technology. As the cornerstone of Industry 4.0, Industrial Internet of Things is revolutionizing how factories operate, enabling unprecedented levels of connectivity, automation, and intelligence on the production floor. This paradigm shift represents more than just technological advancement—it’s fundamentally reshaping the competitive dynamics of global manufacturing.

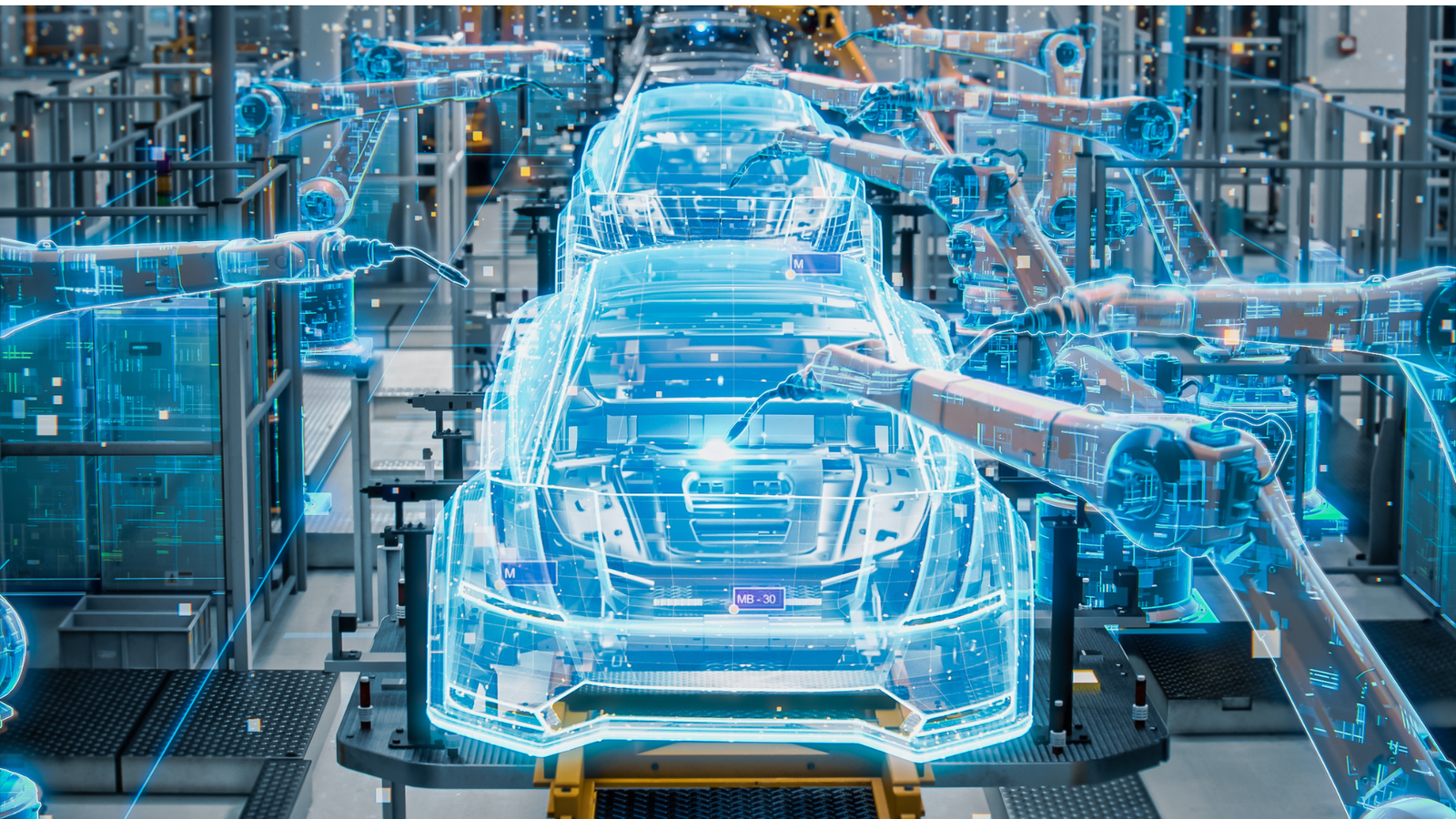

Connected systems powered by IIoT are bridging the gap between physical operations and digital intelligence, creating smart factories that can think, learn, and optimize themselves in real-time. From automotive assembly lines to pharmaceutical production facilities, manufacturers worldwide are leveraging IoT sensors, machine-to-machine communication, and advanced analytics to achieve operational excellence that was unimaginable just a decade ago.

The impact of Industrial IoT transformation extends far beyond simple automation. Today’s connected manufacturing systems integrate thousands of sensors, actuators, and intelligent devices into cohesive networks that generate actionable insights from massive data streams. These systems enable predictive maintenance, reduce unplanned downtime, optimize energy consumption, and improve product quality while simultaneously cutting operational costs.

As global competition intensifies and customer expectations evolve, manufacturers can no longer afford to operate with traditional disconnected systems. The smart manufacturing revolution demands real-time visibility, agile decision-making, and seamless integration across the entire value chain. Industrial IoT platforms provide the technological foundation for this transformation, enabling manufacturers to monitor equipment health, track assets, optimize production processes, and respond to market demands with unprecedented speed and precision.

This comprehensive guide explores how IIoT technology is transforming manufacturing operations, the key components driving this revolution, implementation strategies, real-world applications, and the future trajectory of connected industrial systems. Whether you’re a manufacturing executive, operations manager, or technology professional, the transformative power of Industrial IoT is essential for staying competitive in the digital age.

Industrial IoT in Manufacturing Context

Industrial IoT refers to the network of interconnected sensors, devices, machinery, and software applications specifically designed for industrial environments. Unlike consumer IoT devices found in homes and offices, IIoT systems are engineered to withstand harsh manufacturing conditions while delivering mission-critical reliability and performance.

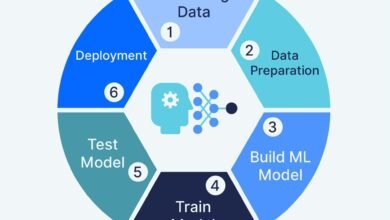

The fundamental architecture of the Industrial Internet of Things consists of four primary layers. The perception layer includes smart sensors and actuators embedded in machines and equipment that collect real-time data on temperature, pressure, vibration, speed, and countless other parameters. The network layer facilitates secure data transmission through industrial protocols and wireless technologies. The platform layer processes and analyzes data using edge computing and cloud computing infrastructure. Finally, the application layer delivers actionable insights through dashboards, analytics tools, and automated control systems.

IIoT in manufacturing enables unprecedented visibility into production operations. Every machine, conveyor belt, robotic arm, and quality inspection station becomes a data source, generating continuous streams of information about operational status, performance metrics, and potential anomalies. This comprehensive data collection creates a digital twin of the physical factory—a virtual replica that mirrors real-world operations in real-time.

The distinction between traditional automation and IIoT-enabled systems is profound. While conventional automation follows predetermined sequences, connected manufacturing systems adapt dynamically based on real-time conditions. They learn from historical patterns, predict future outcomes, and optimize operations autonomously. This intelligence transforms reactive manufacturing into proactive, self-optimizing production environments.

Machine learning algorithms and artificial intelligence amplify the value of IIoT data. These technologies identify subtle patterns that human operators might miss, predict equipment failures before they occur, and recommend optimal production parameters for different scenarios. The synergy between Industrial IoT and AI creates manufacturing systems that continuously improve their own performance.

Core Components of IIoT-Enabled Manufacturing Systems

Smart Sensors and Connected Devices

The foundation of any Industrial IoT deployment consists of smart sensors strategically positioned throughout the manufacturing environment. These sophisticated devices measure physical parameters such as temperature, humidity, pressure, vibration, acoustic emissions, and energy consumption. Unlike traditional sensors, IoT-enabled sensors include processing capabilities, wireless connectivity, and standardized communication protocols that enable seamless integration into broader networks.

Modern IIoT sensors feature advanced capabilities including self-calibration, edge processing, and predictive algorithms. They can detect anomalies locally and trigger alerts without requiring constant communication with central systems, reducing network bandwidth requirements and enabling faster response times. Wireless sensor networks eliminate costly cabling installations and provide flexibility for dynamic factory reconfigurations.

Industrial Gateways and Edge Computing

Edge computing devices serve as critical intermediaries between sensors on the factory floor and cloud platforms. These industrial gateways aggregate data from multiple sensors, perform preliminary processing and filtering, and manage secure communications with enterprise systems. By processing data locally at the edge, these devices reduce latency, minimize bandwidth consumption, and enable real-time decision-making even when cloud connectivity is interrupted.

Edge analytics capabilities allow manufacturers to implement immediate control actions based on sensor data without the delays associated with cloud round-trips. For time-critical applications such as robotics control or safety systems, this edge processing is essential for maintaining operational efficiency and worker safety.

Cloud Platforms and Data Analytics

Cloud computing infrastructure provides the scalability and computational power necessary for processing massive volumes of IIoT data. Industrial IoT platforms such as AWS IoT Core, Microsoft Azure IoT, and Google Cloud IoT offer specialized services for device management, data ingestion, storage, and analytics. These platforms support big data analytics, machine learning model training, and integration with enterprise systems like ERP and MES.

The cloud enables manufacturers to implement sophisticated analytics that would be impractical with on-premises infrastructure alone. Predictive analytics models process historical and real-time data to forecast equipment failures, quality issues, and production bottlenecks. Prescriptive analytics go further, recommending specific actions to optimize outcomes.

Connectivity Protocols and Standards

IIoT networks rely on various communication protocols optimized for industrial requirements. OPC UA (Open Platform Communications Unified Architecture) has emerged as a leading standard for industrial automation, providing secure, reliable, and platform-independent data exchange. MQTT (Message Queuing Telemetry Transport) offers lightweight publish-subscribe messaging ideal for resource-constrained devices and unreliable networks.

Wireless technologies, including 5G networks, Wi-Fi 6, and LoRaWA,N enable flexible connectivity options tailored to specific use cases. 5G industrial networks deliver ultra-low latency and massive device connectivity essential for advanced applications like autonomous mobile robots and augmented reality maintenance guidance.

Key Applications Driving Manufacturing Transformation

Predictive Maintenance and Asset Management

Predictive maintenance represents one of the most valuable applications of Industrial IoT in manufacturing. Traditional maintenance strategies rely on either reactive repairs after failures occur or scheduled preventive maintenance based on time intervals. Both approaches are inefficient—reactive maintenance causes costly unplanned downtime, while preventive maintenance often replaces components that still have useful life remaining.

IIoT-enabled predictive maintenance monitors equipment health continuously through vibration sensors, thermal imaging, acoustic monitoring, and other condition-based measurements. Machine learning algorithms analyze these data streams to identify patterns indicating impending failures, often weeks or months in advance. This enables maintenance teams to schedule repairs during planned downtime, order parts proactively, and avoid catastrophic failures.

Manufacturers implementing predictive maintenance systems report 25-30% reductions in maintenance costs, 70-75% decreases in equipment downtime, and 20-25% improvements in equipment lifespan. These improvements deliver substantial ROI, often paying for IIoT investments within 18-24 months.

Production Optimization and Quality Control

Connected manufacturing systems enable real-time production optimization by continuously monitoring process parameters and product quality. IoT sensors embedded in production lines track critical variables such as temperature, pressure, speed, and material flow rates. When deviations from optimal parameters occur, IIoT systems can automatically adjust settings or alert operators to intervene.

Quality control benefits tremendously from IIoT integration. Computer vision systems inspect products at production speeds impossible for human inspectors, identifying defects as small as a few microns. These systems integrate quality data with production parameters, enabling root cause analysis when quality issues arise. Manufacturers can trace every product to its exact production conditions, facilitating rapid identification and correction of quality problems.

Overall Equipment Effectiveness (OEE) improves significantly with IIoT monitoring. Real-time visibility into availability, performance, and quality enables continuous improvement initiatives based on objective data rather than assumptions. Leading manufacturers achieve OEE improvements of 10-20 percentage points through systematic application of IIoT insights.

Supply Chain Visibility and Inventory Management

Industrial IoT extends beyond the factory floor to transform supply chain operations. RFID tags and GPS trackers enable real-time tracking of raw materials, work-in-progress, and finished goods throughout the supply chain. This visibility reduces inventory carrying costs, prevents stockouts, and enables just-in-time manufacturing strategies.

Smart inventory management systems automatically trigger reordering when supplies reach predetermined thresholds, optimizing working capital while ensuring production continuity. Integration between IIoT systems and supplier platforms enables collaborative planning and reduces lead times through better demand visibility.

Energy Management and Sustainability

Manufacturing facilities are energy-intensive operations, and Industrial IoT provides powerful tools for energy optimization. Smart meters and energy monitoring sensors track consumption at granular levels—individual machines, production cells, or entire facilities. This detailed visibility identifies energy waste, peak demand periods, and opportunities for efficiency improvements.

IIoT-driven energy management enables manufacturers to reduce energy costs by 10-20% through strategies such as load shifting to off-peak periods, optimizing HVAC and compressed air systems, and identifying inefficient equipment. Beyond cost savings, these initiatives support sustainability goals and regulatory compliance as environmental regulations become increasingly stringent.

Worker Safety and Ergonomics

Connected safety systems protect workers through real-time monitoring of environmental conditions and worker activities. Wearable IoT devices track worker locations in hazardous areas, monitor exposure to dangerous substances, and detect falls or other accidents. Environmental sensors measure air quality, noise levels, and temperature to ensure safe working conditions.

Augmented reality systems connected through IIoT networks provide workers with real-time guidance for complex assembly tasks or maintenance procedures, reducing errors and improving safety. These systems overlay digital information onto the physical environment, helping workers identify correct components, follow proper sequences, and avoid hazards.

Implementation Strategies for Industrial IoT Success

Conducting Comprehensive Readiness Assessments

Successful IIoT implementation begins with a thorough assessment of organizational readiness. Manufacturers must evaluate existing infrastructure, identify connectivity gaps, assess data management capabilities, and determine workforce skills requirements. This assessment reveals which areas offer the greatest potential ROI and helps prioritize IIoT initiatives.

Operational technology (OT) and information technology (IT) convergence is essential for Industrial IoT success. Traditionally separate domains, OT and IT must collaborate to ensure connected systems meet both operational requirements and cybersecurity standards. This convergence often requires organizational changes, updated policies, and cross-functional teams.

Starting with Pilot Projects

Rather than attempting enterprise-wide transformation immediately, successful manufacturers start with focused pilot projects addressing specific pain points. A pilot project on a single production line or equipment type allows organizations to demonstrate value, refine implementation approaches, and build internal expertise before scaling.

Pilot project selection should balance potential impact with implementation complexity. Ideal candidates deliver measurable business value within 3-6 months while providing learning opportunities applicable to broader deployment. Common starting points include predictive maintenance for critical assets, quality monitoring on high-value production lines, or energy management for resource-intensive equipment.

Building Scalable Architecture

IIoT architecture must support current requirements while accommodating future growth. Scalable designs separate data collection, processing, storage, and analytics into modular layers that can evolve independently. Cloud-native architectures provide inherent scalability, while hybrid approaches combining edge and cloud processing offer flexibility for different use cases.

Standardization across sensors, protocols, and platforms reduces integration complexity and enables the reuse of analytics models and applications. Manufacturers should establish IIoT governance frameworks defining standards for device selection, data formats, security requirements, and integration patterns.

Developing Data Management Capabilities

The value of Industrial IoT lies not in collecting data but in generating actionable insights. Manufacturers must develop robust data management strategies covering data quality, storage, analytics, and governance. Data lakes and time-series databases optimized for industrial data provide a foundation for advanced analytics.

Data scientists and analytics engineers collaborate with operations experts to develop predictive models and optimization algorithms. This collaboration ensures analytical insights align with operational realities and decision-making processes. Effective organizations establish feedback loops where operational outcomes validate and refine analytical models continuously.

Addressing Cybersecurity Requirements

Industrial cybersecurity is paramount as connected systems create potential attack vectors. Manufacturers must implement defense-in-depth strategies, including network segmentation, encrypted communications, device authentication, and continuous monitoring for suspicious activities. Zero-trust security models assume no device or user is inherently trustworthy, requiring continuous verification.

OT security differs from traditional IT security due to operational continuity requirements and legacy equipment constraints. Security implementations must protect against threats without disrupting production operations or requiring extensive equipment modifications. Regular security assessments, penetration testing, and incident response planning are essential components of comprehensive IIoT security programs.

Overcoming Implementation Challenges

Legacy System Integration

Many manufacturing facilities operate equipment decades old, predating modern connectivity standards. Integrating this legacy equipment into IIoT networks requires creative approaches such as retrofitting sensors, implementing protocol converters, or deploying edge devices that bridge between legacy and modern systems. While challenging, legacy integration is often more cost-effective than wholesale equipment replacement.

Skills Gap and Change Management

Industrial IoT requires workforce capabilities spanning mechanical engineering, electrical engineering, data science, and software development. Many manufacturers face significant skills gaps requiring investment in training, hiring, or partnerships with technology providers. Change management programs help workers adapt to new technologies and processes, addressing concerns about job security and building enthusiasm for digital transformation.

Data Overload and Analytics Complexity

IIoT sensors can generate terabytes of data daily, creating challenges for storage, processing, and analysis. Manufacturers must carefully determine which data to collect, how long to retain it, and which analytics provide genuine business value. Edge processing filters irrelevant data before transmission, while machine learning models automate pattern recognition that would be impossible through manual analysis.

ROI Measurement and Justification

Quantifying IIoT ROI can be complex as benefits often span multiple dimensions—reduced downtime, improved quality, energy savings, and enhanced safety. Comprehensive ROI models should capture both tangible financial returns and strategic benefits such as improved customer satisfaction or accelerated time-to-market. Phased implementation allows organizations to demonstrate early wins that build momentum for broader investment.

Real-World Success Stories and Use Cases

Automotive Manufacturing Excellence

Leading automotive manufacturers have achieved remarkable results through Industrial IoT implementation. One major European automaker deployed predictive maintenance systems across assembly lines, reducing unplanned downtime by 42% and maintenance costs by 28%. IoT sensors monitoring robotic welding equipment detect subtle changes in electrical current or movement patterns, indicating imminent failures, enabling preemptive repairs during scheduled maintenance windows.

Pharmaceutical Quality Assurance

Pharmaceutical manufacturers face stringent regulatory requirements demanding complete traceability and quality documentation. IIoT systems automatically capture and store all production parameters, environmental conditions, and quality measurements, creating comprehensive digital records for regulatory compliance. One pharmaceutical company reduced batch failures by 35% through real-time monitoring and control of critical environmental parameters in cleanrooms.

Food and Beverage Operations

Food and beverage manufacturers use Industrial IoT to ensure product safety and optimize production efficiency. Temperature sensors and humidity monitors throughout cold chain logistics ensure proper storage conditions. Vision systems inspect packaging integrity at production speeds, while predictive analytics optimize ingredient usage and reduce waste. These implementations have helped manufacturers reduce spoilage by 25-30% while improving product consistency.

Electronics Manufacturing Precision

Electronics manufacturers requiring microscopic precision use IIoT monitoring to maintain exact environmental conditions. Even small variations in temperature or humidity can affect product quality. Connected environmental control systems automatically adjust conditions across manufacturing spaces, maintaining tolerances within fractions of a degree. This precision has enabled yield improvements of 5-10 percentage points in semiconductor fabrication.

Future Trends Shaping Industrial IoT Evolution

5G and Advanced Connectivity

5G industrial networks will enable applications currently impractical with existing connectivity. Ultra-low latency supports real-time control of autonomous systems, massive connectivity accommodates exponentially more IoT devices, and network slicing creates dedicated virtual networks for critical applications. Private 5G networks give manufacturers complete control over connectivity infrastructure optimized for their specific requirements.

Artificial Intelligence and Machine Learning Integration

AI-powered IIoT systems will become increasingly autonomous, making complex decisions without human intervention. Deep learning models will identify subtle patterns in multivariate sensor data, predicting failures with greater accuracy and longer lead times. Reinforcement learning algorithms will optimize production parameters automatically, continuously experimenting to discover optimal settings for changing conditions.

Digital Twin Technology Advancement

Digital twins will evolve from simple monitoring systems to sophisticated simulation platforms enabling what-if analysis and virtual experimentation. Manufacturers will test new production layouts, equipment configurations, and operational strategies in digital environments before implementing them physically. This virtual prototyping reduces risks and accelerates innovation.

Edge Intelligence and Autonomous Systems

Edge computing capabilities will expand dramatically, enabling sophisticated processing at the device level. Autonomous mobile robots will navigate factories independently, coordinating with other robots and fixed equipment through IIoT networks. Collaborative robots (cobots) will work safely alongside humans, adjusting behavior based on real-time environmental awareness.

Sustainable Manufacturing Focus

Industrial IoT will play an increasingly critical role in sustainability initiatives. Carbon footprint tracking at product and process levels will enable manufacturers to optimize for environmental impact alongside traditional metrics like cost and quality. Circular economy initiatives will use IoT-enabled tracking to facilitate product recovery, refurbishment, and recycling.

Blockchain Integration for Supply Chain Transparency

Blockchain technology combined with Industrial IoT will create immutable records of product provenance, quality verification, and chain of custody. This transparency addresses growing consumer demand for ethical sourcing and authenticity verification while streamlining regulatory compliance and reducing counterfeiting.

More Read: IoT Security Protecting Connected Devices from Cyber Threats

Conclusion

Industrial IoT represents a fundamental transformation in manufacturing, creating connected systems that deliver unprecedented visibility, control, and optimization across operations. From predictive maintenance and quality control to energy management and supply chain visibility, IIoT applications drive measurable improvements in efficiency, quality, and competitiveness. While implementation challenges exist—including legacy system integration, cybersecurity concerns, and workforce skill requirements—manufacturers successfully deploying Industrial IoT solutions achieve substantial returns through reduced downtime, improved productivity, and enhanced decision-making capabilities.

As technologies like 5G networks, artificial intelligence, and digital twins mature, the transformative potential of Industrial IoT will only accelerate. Manufacturers embracing this connected revolution position themselves to thrive in the increasingly competitive, sustainability-focused, and customer-centric landscape of modern manufacturing. The question is no longer whether to adopt Industrial IoT, but how quickly organizations can implement these transformative technologies to maintain competitive advantage in the Industry 4.0 era.