Industrial IoT vs Consumer IoT: What’s Different?

Industrial IoT vs Consumer IoT: Discover the key differences in security, scalability, and applications. Learn which IoT solution fits your needs in 2026.

The Internet of Things has fundamentally changed how we interact with technology, but not all IoT implementations are created equal. If you’ve ever wondered why your smart thermostat seems so different from the sensors monitoring a factory floor, you’re asking exactly the right question.

Industrial IoT and Consumer IoT represent two distinct branches of connected technology, each designed for vastly different purposes. While your fitness tracker counts steps and your smart speaker plays music, industrial systems are quietly managing power grids, optimizing manufacturing lines, and keeping critical infrastructure running smoothly.

The distinction matters more than you might think. Understanding the differences between Industrial IoT vs Consumer IoT isn’t just academic—it affects everything from the devices you buy to the career paths you might pursue. These two worlds operate under different rules, face unique challenges, and solve completely different problems.

In this comprehensive guide, we’ll break down exactly what separates industrial and consumer IoT implementations. You’ll learn about the technical requirements that drive their design, the security considerations that keep them running, and the real-world applications that make each one essential. Whether you’re a business leader evaluating IoT investments, a developer choosing a specialization, or simply curious about the connected world around you, this article will give you the clarity you need to understand these two critical branches of IoT technology.

What Is Consumer IoT?

Consumer IoT refers to the connected devices designed for personal use in homes and everyday life. These are the smart gadgets that make life more convenient, entertaining, and efficient for individual users.

When you think about Consumer IoT, you’re thinking about products like:

- Smart home devices (thermostats, lights, locks)

- Wearable fitness trackers and smartwatches

- Voice-activated assistants

- Connected appliances (refrigerators, washing machines)

- Smart TVs and entertainment systems

- Personal security cameras

The primary goal of Consumer IoT is to enhance the user experience. These devices prioritize ease of use, affordability, and quick setup. You don’t need an engineering degree to install a smart bulb or configure a fitness tracker—that’s by design.

Consumer IoT devices typically connect through home Wi-Fi networks and communicate with cloud services that process data and enable remote control through mobile apps. The data they collect is usually personal and used to provide individualized services, recommendations, or automation.

Most importantly, Consumer IoT products operate in relatively controlled environments. Your smart speaker doesn’t need to withstand extreme temperatures, and your fitness tracker doesn’t need to run continuously for decades without maintenance.

What Is Industrial IoT?

Industrial IoT (often abbreviated as IIoT) represents connected technology deployed in industrial settings like manufacturing plants, energy facilities, transportation systems, and healthcare institutions. These implementations are designed to optimize operations, improve safety, and enable data-driven decision-making at scale.

Industrial IoT systems might include:

- Manufacturing equipment sensors monitoring production lines

- Predictive maintenance systems in factories

- Smart grid technology in power distribution

- Fleet management systems for logistics companies

- Environmental monitoring in oil and gas facilities

- Hospital equipment tracking and patient monitoring systems

The fundamental difference is purpose. While Consumer IoT aims to make individual lives more convenient, Industrial IoT focuses on operational efficiency, safety, and reliability at an enterprise or infrastructure level.

Industrial IoT deployments often involve thousands or even millions of connected sensors and devices working together. These systems must operate reliably in harsh conditions—extreme temperatures, vibration, moisture, and electromagnetic interference. A sensor failure in a factory could halt production and cost thousands of dollars per minute.

According to research from McKinsey & Company, Industrial IoT could generate up to $12.6 trillion in economic value globally by 2030, highlighting the massive scale and importance of these implementations.

Industrial IoT solutions also integrate with existing enterprise systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems), creating comprehensive digital ecosystems that transform entire industries.

7 Key Differences Between Industrial IoT vs Consumer IoT

Let’s examine the critical distinctions that separate Industrial IoT from Consumer IoT across multiple dimensions.

1. Security and Data Protection

Security represents perhaps the most significant difference between Industrial IoT and Consumer IoT implementations.

Consumer IoT security focuses on protecting personal privacy and preventing unauthorized access to individual devices. While important, a compromised smart speaker or fitness tracker primarily affects one user or household. The security standards for Consumer IoT devices have historically been inconsistent, though regulations are improving this landscape.

Industrial IoT security operates at an entirely different level. A breach in an Industrial IoT system could:

- Shut down critical infrastructure

- Compromise safety systems in factories

- Expose proprietary manufacturing processes

- Cause environmental disasters

- Impact thousands or millions of people

Industrial IoT implementations require multi-layered security approaches including:

- Network segmentation to isolate critical systems

- Encryption for data in transit and at rest

- Authentication protocols that meet industry standards

- Regular security audits and penetration testing

- Compliance with regulations like IEC 62443 for industrial automation

The stakes are fundamentally different. A Consumer IoT device might get a security patch every few months. An Industrial IoT system requires continuous monitoring, immediate response to threats, and security protocols that can protect against both cyber and physical attacks.

2. Scale and Complexity

The scale of Industrial IoT vs Consumer IoT differs dramatically.

Consumer IoT typically involves dozens of devices at most—maybe you have 20 smart devices in your home. Setup is straightforward, management is simple, and troubleshooting usually means restarting a device or checking your Wi-Fi connection.

Industrial IoT operates at an entirely different magnitude:

- A single factory might deploy 10,000+ sensors

- A smart city implementation could involve millions of connected devices

- Oil and gas companies manage sensors across hundreds of square miles

- Agricultural IoT systems monitor thousands of acres in real-time

This scale introduces complexity that doesn’t exist in Consumer IoT:

- Device management requires sophisticated platforms

- Network architecture must handle massive data volumes

- Interoperability between different manufacturer systems becomes critical

- Maintenance scheduling requires predictive algorithms

Managing an Industrial IoT deployment isn’t something one person can do from a smartphone app. It requires dedicated teams, specialized software platforms, and carefully architected systems that can scale reliably.

3. Reliability and Uptime Requirements

Reliability expectations differ drastically between Industrial IoT and Consumer IoT.

If your Consumer IoT smart bulb stops working, it’s annoying. You might have to flip a physical switch instead. If your fitness tracker has a glitch, you miss a day of data. These inconveniences don’t typically create serious consequences.

Industrial IoT systems must maintain uptime levels that would be unthinkable for consumer products:

- Manufacturing systems often require 99.9% or higher uptime

- Healthcare IoT devices must operate continuously for patient safety

- Power grid management systems cannot afford failures

- Transportation systems need constant reliability for public safety

An Industrial IoT failure can mean:

- Production line shutdowns costing $20,000+ per minute

- Safety incidents putting workers at risk

- Environmental compliance violations

- Service disruptions affecting thousands of customers

This drives completely different design philosophies. Industrial IoT components are engineered for:

- Redundancy at every critical point

- Failover systems that activate automatically

- Self-diagnostic capabilities that predict failures before they occur

- Ruggedized hardware that operates in harsh conditions

- Long operational lifespans measured in decades, not years

According to Deloitte, organizations implementing Industrial IoT prioritize reliability and uptime as their top concerns, far above the convenience factors that drive Consumer IoT adoption.

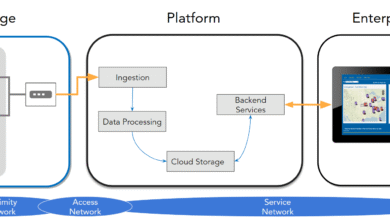

4. Data Volume and Processing

The data generated by Industrial IoT vs Consumer IoT varies enormously in volume, velocity, and value.

Consumer IoT devices generate relatively modest data streams:

- A fitness tracker might record data points every few seconds

- A smart thermostat updates temperature readings every minute

- A security camera streams video when motion is detected

This data is typically sent to cloud services for processing, storage, and analysis. The infrastructure requirements are manageable because individual users don’t generate massive data volumes.

Industrial IoT generates data at scales that would overwhelm traditional systems:

- A single jet engine produces 1 terabyte of data per flight

- Manufacturing sensors generate millions of data points per day

- Smart city systems collect petabytes of information monthly

- Oil rig sensors monitor thousands of parameters continuously

This volume necessitates different architectural approaches:

- Edge computing processes data locally before sending to central systems

- Time-series databases optimized for sensor data

- Real-time analytics that can process streaming data instantly

- Data compression and filtering to manage bandwidth

Industrial IoT also focuses on operational technology data—information about physical processes, equipment performance, and production metrics. This differs fundamentally from the personal preference data that Consumer IoT collects.

The data value also differs. While Consumer IoT data helps companies understand user behavior and improve products, Industrial IoT data directly impacts operational efficiency, safety, and profitability. A single insight from Industrial IoT analytics might save a company millions of dollars annually.

5. Cost and Investment

The cost structures for Industrial IoT vs Consumer IoT reflect their different purposes and requirements.

Consumer IoT devices compete on price:

- Smart bulbs cost $10-50

- Fitness trackers range from $50-400

- Smart speakers sell for $30-200

- Complete smart home setups cost $500-3,000

Manufacturers must keep Consumer IoT prices low because individuals are paying out of pocket. The business model often relies on selling hardware at minimal margins while generating revenue through subscriptions, data monetization, or ecosystem lock-in.

Industrial IoT involves completely different economics:

- Individual industrial sensors can cost $1,000-10,000+

- Complete factory automation systems run $500,000-10 million

- Enterprise IoT platforms require six-figure annual subscriptions

- Implementation services add significant consulting costs

However, Industrial IoT investments are justified by tangible returns:

- Reduced downtime saving millions annually

- Energy efficiency improvements lowering operational costs

- Predictive maintenance extending equipment lifespans

- Quality improvements reducing waste and rework

- Safety enhancements preventing costly incidents

ROI (Return on Investment) calculations drive Industrial IoT purchases. Companies don’t buy these systems for convenience—they buy them because the economic benefits justify the investment.

The total cost of ownership also differs. Consumer IoT might require minimal ongoing costs, while Industrial IoT includes continuous expenses for maintenance, upgrades, security monitoring, and support services.

6. Connectivity and Network Requirements

Network infrastructure for Industrial IoT vs Consumer IoT varies significantly in complexity and requirements.

Consumer IoT typically relies on:

- Standard Wi-Fi for most home devices

- Bluetooth for wearables and nearby connections

- 4G/5G cellular for mobile devices

- Cloud connectivity through residential internet

These networks are convenient but not necessarily optimized for IoT. Your smart devices share bandwidth with laptops, phones, and streaming services. Occasional connectivity drops are annoying but acceptable.

Industrial IoT demands purpose-built networks:

- Industrial Ethernet with guaranteed bandwidth and latency

- 5G private networks for factory automation

- LoRaWAN for long-range, low-power sensor networks

- Cellular IoT (NB-IoT, LTE-M) for wide-area coverage

- Time-Sensitive Networking (TSN) for critical applications

Key network requirements for Industrial IoT include:

- Deterministic latency: Manufacturing robots need responses in milliseconds

- High availability: Networks must operate 24/7/365

- Bandwidth management: Prioritization for critical traffic

- Edge processing: Reducing dependence on cloud connectivity

- Network redundancy: Backup connections for failover

Industrial IoT networks often incorporate multiple technologies in hybrid architectures. A factory might use wired Ethernet for production equipment, LoRaWAN for building environmental sensors, and 5G for mobile robots—all integrated into a unified system.

The network security requirements also differ. Industrial IoT networks implement strict access controls, network segmentation, and monitoring that goes far beyond typical Consumer IoT home networks.

7. Standards and Interoperability

Standards and interoperability present ongoing challenges in both Industrial IoT and Consumer IoT, but the approaches differ.

Consumer IoT has struggled with fragmentation:

- Multiple competing standards (Zigbee, Z-Wave, Thread)

- Proprietary ecosystems (Apple HomeKit, Google Home, Amazon Alexa)

- Limited device compatibility across platforms

- Gradual movement toward unified standards like Matter

For consumers, this means carefully checking compatibility before purchases and sometimes dealing with devices that won’t work together. It’s frustrating but typically not catastrophic.

Industrial IoT takes standards more seriously because interoperability is essential:

- OPC UA (Unified Architecture): Standard for industrial machine-to-machine communication

- MQTT: Lightweight messaging protocol for IoT

- CoAP: Protocol for constrained devices

- Industrial automation standards: IEC 61131, IEC 62541

- Industry-specific standards: Healthcare (HL7, FHIR), Energy (IEC 61850)

Organizations like the Industrial Internet Consortium and Open Connectivity Foundation work to establish standards that enable different Industrial IoT systems to communicate effectively.

Interoperability matters more in Industrial IoT because:

- Companies deploy equipment from multiple vendors

- Systems must integrate with legacy infrastructure decades old

- Data exchange between systems is critical for operations

- Vendor lock-in creates unacceptable business risks

Industrial IoT buyers often require standards compliance before making purchasing decisions, creating market incentives for manufacturers to adopt open protocols rather than proprietary approaches that dominate Consumer IoT.

Real-World Applications: Industrial IoT vs Consumer IoT in Action

Understanding Industrial IoT vs Consumer IoT becomes clearer when examining practical applications.

Consumer IoT Applications

Consumer IoT has transformed daily life with applications like:

Smart Home Automation

- Automated lighting that adjusts to schedules and preferences

- Smart thermostats learning temperature preferences and optimizing energy use

- Voice-controlled entertainment systems

- Connected door locks enabling keyless entry

Personal Health and Fitness

- Fitness trackers monitoring steps, heart rate, and sleep patterns

- Smartwatches providing notifications and health alerts

- Connected scales tracking weight trends

- Blood pressure monitors sharing data with healthcare apps

Connected Vehicles

- Navigation systems with real-time traffic updates

- Remote vehicle diagnostics and maintenance alerts

- Entertainment systems with streaming connectivity

- Telematics systems for usage-based insurance

These Consumer IoT applications enhance individual experiences, provide convenience, and create personalized services. The value is measured in time saved, comfort gained, and personal insights discovered.

Industrial IoT Applications

Industrial IoT tackles fundamentally different challenges:

Predictive Maintenance Manufacturing companies use Industrial IoT sensors to monitor equipment vibration, temperature, and performance. Machine learning algorithms analyze this data to predict failures before they occur, enabling maintenance during planned downtime rather than after costly breakdowns.

A typical implementation might reduce unplanned downtime by 30-50% and extend equipment lifespan by 20-30%.

Smart Grid Management Utility companies deploy Industrial IoT across power generation, transmission, and distribution systems. Smart meters provide real-time usage data, sensors monitor grid health, and automated systems balance load and optimize distribution.

These Industrial IoT systems improve grid reliability, integrate renewable energy sources more effectively, and enable dynamic pricing that reduces peak demand.

Supply Chain Optimization Logistics companies use Industrial IoT for real-time tracking of shipments, monitoring environmental conditions for sensitive cargo, optimizing routes based on traffic and weather, and automating warehouse operations.

Industrial IoT in supply chain can reduce logistics costs by 15-30% while improving delivery reliability and reducing waste from damaged goods.

Agricultural Technology Modern farms deploy Industrial IoT sensors monitoring soil moisture, weather conditions, crop health, and equipment performance. Precision agriculture uses this data to optimize irrigation, reduce pesticide use, and improve yields.

Healthcare Systems Hospitals implement Industrial IoT for patient monitoring, equipment tracking, environmental controls, and predictive maintenance of critical medical devices. These systems improve patient outcomes, reduce costs, and enhance operational efficiency.

The distinction is clear: Consumer IoT serves individuals while Industrial IoT optimizes operations, improves safety, and creates measurable business value at enterprise scale.

Choosing Between Industrial IoT and Consumer IoT Solutions

Understanding when to use Industrial IoT vs Consumer IoT depends on your specific needs and context.

Choose Consumer IoT when:

- You need solutions for personal or small-scale residential use

- Convenience and user experience are primary concerns

- Budget constraints require affordable options

- Quick deployment without technical expertise is important

- The impact of device failure is minimal

- You’re serving individual consumers or small households

Consumer IoT works perfectly for smart homes, personal health tracking, individual entertainment systems, and consumer vehicles. These applications don’t require enterprise-grade reliability or security.

Choose Industrial IoT when:

- You need solutions for business operations or critical infrastructure

- Reliability and uptime are essential

- Security requirements meet enterprise or regulatory standards

- You’re managing hundreds or thousands of devices

- Device failures could cause significant financial or safety impacts

- You need integration with existing enterprise systems

- ROI justification is based on operational improvements

Industrial IoT is appropriate for manufacturing, energy, healthcare, transportation, agriculture, and any enterprise operation where connected technology directly impacts business outcomes.

Some scenarios blur these lines. A small business might start with Consumer IoT devices for basic needs—security cameras, smart thermostats, occupancy sensors. As operations scale and requirements increase, they might transition to Industrial IoT solutions that offer better reliability, security, and management capabilities.

The key is honestly assessing your requirements. Don’t purchase Industrial IoT solutions when Consumer IoT meets your needs—you’ll pay unnecessarily. But don’t try to scale Consumer IoT into industrial applications where it will inevitably fail.

The Future of Industrial IoT vs Consumer IoT

Both Industrial IoT and Consumer IoT continue evolving rapidly, though their trajectories differ.

Consumer IoT trends include:

- Improved interoperability through standards like Matter

- Enhanced privacy controls responding to consumer concerns

- AI integration making devices more intelligent and autonomous

- Energy harvesting reducing battery replacement needs

- Voice and gesture control expanding beyond current implementations

Industrial IoT developments focus on:

- Edge AI enabling real-time decision-making at the device level

- 5G integration providing ultra-reliable low-latency connectivity

- Digital twins creating virtual replicas of physical systems

- Blockchain for secure, decentralized data management

- Augmented reality overlays for maintenance and training

The convergence of technologies like artificial intelligence, 5G networks, and edge computing benefits both domains but amplifies their differences. Consumer IoT becomes more seamless and intuitive, while Industrial IoT becomes more powerful and capable of handling increasingly complex operations.

Importantly, the divide between Industrial IoT vs Consumer IoT will likely persist. The fundamental differences in requirements, scale, and purpose make convergence unlikely. Instead, expect continued specialization with technologies optimized for their specific domains.

One interesting trend is prosumer IoT—solutions targeting small businesses, professional creators, and power users who need capabilities beyond Consumer IoT but don’t require full Industrial IoT implementations. This middle ground could grow significantly in coming years.

Common Misconceptions About Industrial IoT vs Consumer IoT

Several misunderstandings about Industrial IoT and Consumer IoT persist:

Misconception 1: Industrial IoT is just consumer IoT at larger scale

Reality: Industrial IoT differs fundamentally in design, not just quantity. Industrial devices require different engineering, standards, and capabilities than consumer products.

Misconception 2: Consumer IoT is inherently less secure

Reality: While Industrial IoT typically implements stronger security, Consumer IoT security varies widely by manufacturer. Some consumer devices meet high security standards, while some industrial devices have vulnerabilities. The difference lies in requirements and regulations, not inherent capabilities.

Misconception 3: Industrial IoT is always more expensive

Reality: While individual Industrial IoT components cost more, total cost of ownership depends on context. For small-scale applications, Consumer IoT offers better value. For large deployments, Industrial IoT often provides lower per-device costs when accounting for reliability, management, and lifespan.

Misconception 4: Consumer IoT doesn’t generate valuable business insights

Reality: Consumer IoT generates enormous value through data analytics, though differently than Industrial IoT. Consumer device manufacturers and service providers extract significant insights from usage patterns, though these insights serve different purposes than operational data from Industrial IoT.

Misconception 5: The technologies are incompatible

Reality: While Industrial IoT and Consumer IoT use different protocols and architectures, they can integrate when needed. Many businesses successfully combine consumer-grade devices for non-critical applications with industrial-grade systems for operations.

Understanding these distinctions helps make informed decisions about which type of IoT suits your needs.

Conclusion

The differences between Industrial IoT vs Consumer IoT extend far beyond simple application domains. Consumer IoT prioritizes convenience, affordability, and user experience for individual consumers, while Industrial IoT focuses on reliability, security, and operational efficiency for enterprise applications. Industrial IoT systems must meet stringent requirements for uptime, security, and scale that consumer devices simply don’t face. From network architecture to cost structures, from data volumes to regulatory compliance, these two branches of IoT technology operate under fundamentally different constraints and serve distinct purposes. Understanding these differences is essential whether you’re purchasing IoT devices for your home or evaluating.

Industrial IoT investments for your business, or simply trying to make sense of the connected world around you. As both Consumer IoT and Industrial IoT continue evolving, their core distinctions will persist, with each becoming increasingly sophisticated within its domain. The future belongs to both, serving their respective roles in our increasingly connected world.