The landscape of modern manufacturing has undergone a revolutionary transformation with the advent of industrial robotics. These sophisticated automated systems are no longer confined to science fiction but have become the backbone of efficient production processes across diverse industries. Industrial robots represent a convergence of advanced engineering, artificial intelligence, and precision mechanics that are reshaping how products are manufactured, assembled, and delivered to global markets.

Manufacturing automation through robotic systems has emerged as a critical competitive advantage for companies seeking to optimize their operations, reduce costs, and maintain consistent quality standards. From automotive assembly lines to pharmaceutical packaging facilities, industrial robotics technology is driving unprecedented levels of efficiency and accuracy that human workers alone cannot achieve. The integration of smart manufacturing principles with robotic automation has created a new paradigm where machines and humans collaborate seamlessly to maximize productivity.

Today’s industrial robots are equipped with advanced sensors, machine learning capabilities, and sophisticated control systems that enable them to perform complex tasks with remarkable precision. These automated manufacturing solutions are not merely replacing human workers but are augmenting human capabilities, allowing skilled technicians to focus on higher-value activities while robots handle repetitive, dangerous, or precision-critical operations. The robotics industry has evolved to offer scalable solutions that cater to both large-scale enterprises and small-to-medium manufacturers.

The impact of industrial automation extends beyond mere productivity gains. Companies implementing robotic manufacturing systems report significant improvements in workplace safety, product quality consistency, and operational flexibility. As we advance into an era defined by Industry 4.0 principles, industrial robotics continues to evolve, incorporating cutting-edge technologies such as artificial intelligence, Internet of Things connectivity, and predictive analytics to create truly intelligent production automation ecosystems that adapt and optimize in real-time.

Industrial Robotics Fundamentals

What Are Industrial Robots

Industrial robots are programmable, multi-axis machines designed to perform specific manufacturing tasks with high precision, repeatability, and speed. Unlike traditional fixed automation systems, these robotic systems offer remarkable flexibility, allowing manufacturers to reprogram and redeploy them across different production processes as needs evolve. Modern industrial robotics encompasses a broad spectrum of machine types, from simple pick-and-place units to sophisticated collaborative robots (cobots) that work alongside human operators.

The core architecture of industrial robots typically includes a manipulator arm, end-effector (gripper or tool), control system, and sensor array. These components work in harmony to execute precise movements and operations that would be challenging, dangerous, or impossible for human workers to perform consistently. Robotic automation systems are designed to operate continuously for extended periods, maintaining consistent performance levels that contribute significantly to overall manufacturing efficiency.

Advanced industrial robotics technology now incorporates artificial intelligence and machine learning algorithms that enable robots to adapt to variations in their environment and optimize their performance over time. This evolution has transformed industrial robots from simple programmable machines into intelligent systems capable of making real-time decisions and adjustments during production processes.

Key Components of Robotic Systems

The effectiveness of manufacturing automation relies heavily on the sophisticated integration of multiple technological components within robotic systems. The manipulator, serving as the primary mechanical structure, provides the necessary degrees of freedom for complex movements and positioning. Control systems act as the brain of industrial robots, processing sensor data, executing programmed instructions, and coordinating movements with other automated systems in the production line.

Sensors play a crucial role in modern industrial robotics, providing real-time feedback about the robot’s environment, position, and the objects being manipulated. Vision systems, force sensors, and proximity detectors enable robotic automation to achieve levels of precision and adaptability that were previously impossible. These sensory capabilities allow industrial robots to perform quality control functions, adapt to variations in incoming materials, and ensure consistent manufacturing processes.

End-effectors, the tools that interact directly with products and materials, represent another critical component that determines the versatility and effectiveness of robotic manufacturing systems. From simple grippers to specialized welding torches, painting systems, and assembly tools, the variety of end-effectors available enables industrial robotics to address virtually any production automation requirement across different industries.

Types and Categories of Industrial Robots

Articulated Robots

Articulated robots represent the most versatile and widely deployed category in industrial robotics, featuring multiple rotary joints that provide exceptional flexibility and range of motion. These robotic systems typically possess six or more degrees of freedom, enabling them to perform complex manipulation tasks that closely mimic human arm movements. In manufacturing automation applications, articulated robots excel at assembly operations, material handling, and quality inspection tasks where precise positioning and orientation control are essential.

The design flexibility of articulated robots makes them ideal for automated manufacturing solutions across diverse industries. Their ability to reach around obstacles and work in confined spaces while maintaining high precision makes them particularly valuable in automotive assembly, electronics manufacturing, and aerospace production processes. Modern articulated robots incorporate advanced path planning algorithms and collision avoidance systems that optimize their movements for maximum efficiency while ensuring safe operation in collaborative robotics environments.

Industrial robotics manufacturers have developed specialized variants of articulated robots optimized for specific applications. Heavy-duty models designed for automotive manufacturing automation can handle payloads exceeding 500 kilograms, while precision variants used in electronics assembly can achieve repeatability tolerances within micrometers. This specialization ensures that robotic automation solutions can be tailored to meet the exact requirements of different production automation scenarios.

SCARA Robots

SCARA robots (Selective Compliance Assembly Robot Arm) represent a specialized category of industrial robots designed specifically for high-speed, high-precision assembly operations in manufacturing processes. These robotic systems feature a unique design that provides rigidity in the vertical direction while allowing compliance in the horizontal plane, making them ideal for insertion and assembly tasks in automated manufacturing environments.

The inherent speed advantage of SCARA robots has made them indispensable in electronics manufacturing automation, where rapid pick-and-place operations and precise component placement are critical for productivity. These industrial robotics solutions can achieve cycle times measured in fractions of a second while maintaining exceptional accuracy, making them perfect for production processes involving printed circuit board assembly, component testing, and packaging operations.

Modern SCARA robots incorporate advanced vision systems and force feedback mechanisms that enable them to perform complex assembly tasks with minimal human intervention. The integration of these robotic automation systems with smart manufacturing platforms allows for real-time optimization of production processes and immediate adjustment to variations in component specifications or assembly requirements.

Cartesian Robots

Cartesian robots, also known as gantry robots, represent a fundamental approach to industrial robotics that utilizes linear motion along three perpendicular axes to achieve precise positioning and movement. These robotic systems offer exceptional accuracy and repeatability, making them ideal for applications requiring precise material handling, dispensing, and assembly operations in manufacturing automation environments.

The simple, robust design of Cartesian robots provides several advantages in production automation applications. Their linear motion system reduces complexity while maximizing precision, enabling them to achieve positioning accuracies measured in micrometers. This precision makes Cartesian robots particularly valuable in applications such as 3D printing, CNC machine tending, and precision assembly operations where exact positioning is critical for manufacturing processes.

Industrial robotics implementations using Cartesian robots often feature modular designs that can be easily scaled and reconfigured to accommodate changing production requirements. The ability to extend the working envelope by simply adding linear axis modules makes these automated systems highly adaptable to evolving manufacturing automation needs while maintaining consistent performance and precision.

Collaborative Robots (Cobots)

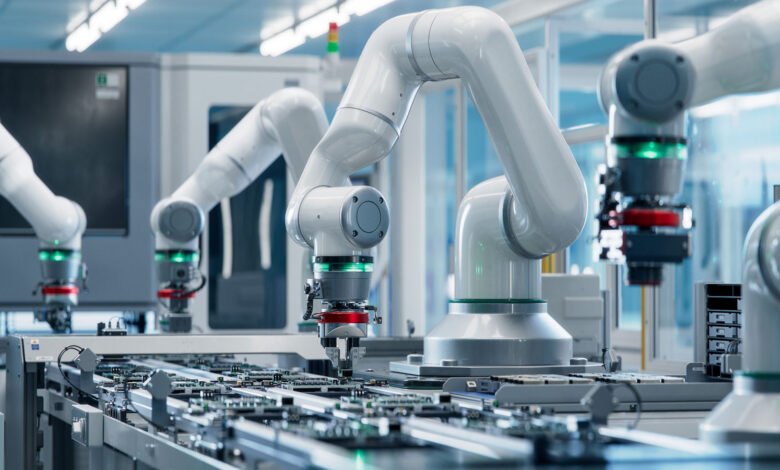

Collaborative robots, commonly referred to as cobots, represent a revolutionary advancement in industrial robotics that enables safe, direct interaction between robots and human workers in manufacturing environments. These robotic systems are specifically designed with advanced safety features, including force limiting, collision detection, and speed monitoring capabilities that allow them to operate without traditional safety barriers in production processes.

The emergence of collaborative robots has democratized manufacturing automation by making robotic automation accessible to smaller manufacturers and enabling flexible production systems that can adapt quickly to changing product requirements. Cobots typically feature intuitive programming interfaces that allow non-technical personnel to teach and reprogram the robots, significantly reducing the implementation time and cost associated with traditional industrial robotics deployments.

Collaborative robotics applications span across diverse industries, from automotive assembly and electronics manufacturing to food processing and pharmaceutical packaging. The ability of cobots to work alongside human operators while handling repetitive or ergonomically challenging tasks has created new possibilities for smart manufacturing implementations that optimize both productivity and worker satisfaction in modern production automation environments.

Applications Across Manufacturing Industries

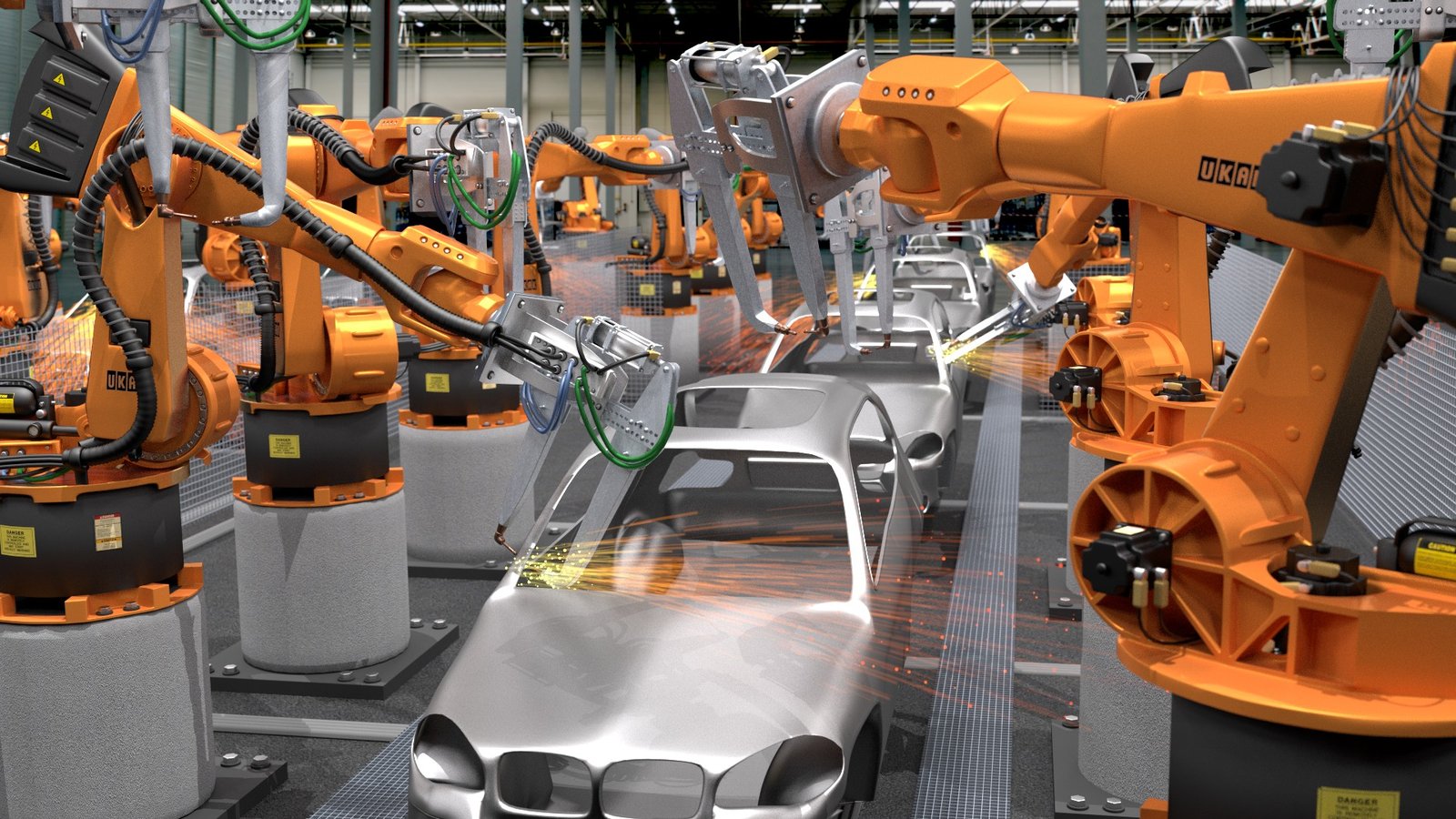

Automotive Manufacturing

The automotive industry stands as a pioneer in industrial robotics adoption, with robotic automation systems playing integral roles throughout the entire production process, from stamping and welding to painting and final assembly. Manufacturing automation in automotive plants has achieved unprecedented levels of efficiency and quality consistency, with industrial robots performing complex tasks such as spot welding, material handling, and precision assembly operations that require both speed and accuracy.

Robotic welding systems in automotive manufacturing processes can perform hundreds of welds per vehicle with millimeter precision, ensuring structural integrity and safety standards that would be difficult to achieve through manual operations. The integration of industrial robotics with advanced quality control systems enables real-time monitoring and adjustment of welding parameters, resulting in consistent joint quality and reduced rework requirements across production lines.

Modern automotive manufacturing automation incorporates collaborative robots that work alongside human technicians for final assembly operations, combining the precision and consistency of robotic systems with human problem-solving capabilities. This hybrid approach to production automation enables automotive manufacturers to maintain flexibility while achieving the high-volume production requirements of the modern automotive market.

Electronics and Technology Manufacturing

Electronics manufacturing represents one of the most demanding applications for industrial robotics, requiring extreme precision, clean room compatibility, and the ability to handle delicate components measuring just micrometers. Robotic automation systems in electronics production processes must achieve positioning accuracies that exceed human capabilities while maintaining the speed necessary for high-volume manufacturing operations.

SCARA robots and precision articulated robots dominate electronics manufacturing automation, performing tasks such as semiconductor die placement, surface mount component assembly, and circuit board testing. These industrial robotics applications often incorporate advanced vision systems and force feedback mechanisms that enable robots to detect and correct for variations in component dimensions and placement requirements during production processes.

The integration of industrial robots with advanced inspection systems in electronics manufacturing enables 100% quality control during production automation, identifying defective components and assembly errors in real-time. This capability significantly reduces the cost associated with field failures and warranty claims while ensuring consistent product quality across high-volume manufacturing processes.

Aerospace and Defense Manufacturing

Aerospace manufacturing automation demands exceptional precision and reliability due to the critical nature of aerospace components and systems. Industrial robotics applications in aerospace manufacturing include composite material layup, precision machining, drilling and fastening operations, and quality inspection processes that require tolerances measured in thousandths of an inch.

Robotic systems used in aerospace production processes must accommodate the large size and complex geometries typical of aircraft components while maintaining the precision necessary for safety-critical applications. Advanced industrial robots equipped with specialized end-effectors can perform automated drilling and fastening operations on aircraft fuselages and wings, ensuring consistent hole quality and fastener installation that meets stringent aerospace quality standards.

The implementation of manufacturing automation in aerospace production has enabled manufacturers to reduce cycle times while improving consistency and traceability throughout production processes. Robotic automation systems integrated with manufacturing execution systems provide complete documentation of all manufacturing operations, supporting the rigorous quality and compliance requirements characteristic of aerospace manufacturing processes.

Food and Beverage Processing

Food and beverage manufacturing presents unique challenges for industrial robotics implementation, including hygiene requirements, temperature variations, and the need to handle products with varying shapes, sizes, and fragility. Robotic automation systems designed for food processing applications must meet strict sanitary standards while providing the flexibility to handle diverse product lines and packaging configurations.

Industrial robots in food processing excel at repetitive tasks such as packaging, palletizing, and case packing, where consistency and speed directly impact productivity and cost-effectiveness. Advanced robotic systems equipped with vision systems can sort and package products based on size, color, and quality criteria, enabling automated quality control throughout production processes.

The adoption of collaborative robots in food manufacturing has enabled new applications where robots work alongside human operators for tasks requiring both precision and flexibility. These manufacturing automation solutions provide improved ergonomics for human workers while maintaining the hygiene and food safety standards required in modern food processing production environments.

Technological Advancements and Innovation

Artificial Intelligence Integration

The integration of artificial intelligence with industrial robotics represents a transformative advancement that is reshaping manufacturing automation capabilities across all industries. AI-powered robotic systems can analyze vast amounts of sensor data in real-time, enabling them to make intelligent decisions about production processes and adapt their behavior based on changing conditions or requirements.

Machine learning algorithms integrated into industrial robots enable continuous improvement of performance over time, with robots learning from experience to optimize their movements, reduce cycle times, and improve quality outcomes. This capability transforms traditional robotic automation from static programmed systems into dynamic, self-improving automated manufacturing solutions that become more efficient with experience.

Smart manufacturing implementations utilizing AI-enabled industrial robotics can predict maintenance requirements, optimize production schedules, and automatically adjust production processes to accommodate variations in raw materials or product specifications. This level of intelligence in manufacturing automation represents a significant step toward fully autonomous production systems that can operate with minimal human intervention while maintaining optimal performance.

Advanced Sensor Technology

Modern industrial robotics increasingly relies on sophisticated sensor technologies that provide robots with unprecedented awareness of their environment and the objects they manipulate. Advanced vision systems, including 3D imaging and hyperspectral cameras, enable robotic systems to perform complex inspection and quality control tasks that were previously requiring human operators.

Force and tactile sensors integrated into industrial robots provide the sensitivity necessary for delicate assembly operations and enable robotic automation to adapt to variations in component dimensions and material properties. These sensors allow robots to perform tasks such as precise insertion operations, surface finishing, and quality assessment with capabilities that often exceed human sensory abilities.

The development of wireless sensor networks and IoT connectivity in industrial robotics enables real-time data sharing between robotic systems and other manufacturing automation equipment. This connectivity facilitates coordinated operations across entire production lines and enables system-wide optimization of manufacturing processes based on real-time performance data from all connected systems.

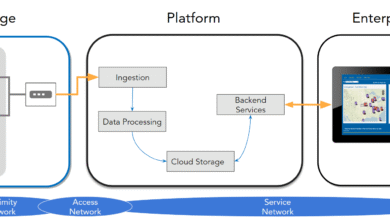

Internet of Things (IoT) Connectivity

IoT connectivity has revolutionized industrial robotics by enabling seamless integration of robotic systems with broader manufacturing automation ecosystems. Connected industrial robots can share operational data, performance metrics, and maintenance requirements with central control systems, enabling comprehensive monitoring and optimization of production processes.

The implementation of IoT-enabled robotic automation facilitates predictive maintenance strategies that can identify potential equipment failures before they occur, significantly reducing unplanned downtime and maintenance costs. Real-time monitoring of industrial robotics performance enables immediate identification of efficiency improvements and optimization opportunities across manufacturing processes.

Smart manufacturing platforms utilizing IoT-connected industrial robots can implement dynamic production scheduling that automatically adjusts production processes based on real-time demand, inventory levels, and equipment availability. This level of integration enables manufacturing automation systems to respond quickly to changing market conditions while maintaining optimal efficiency and resource utilization.

Benefits and Advantages of Industrial Robotics

Enhanced Productivity and Efficiency

Industrial robotics delivers substantial productivity improvements through consistent, high-speed operation capabilities that far exceed human performance in repetitive tasks. Robotic automation systems can operate continuously for extended periods without fatigue, breaks, or performance degradation, enabling manufacturing processes to achieve significantly higher output rates while maintaining consistent quality standards.

The precision and repeatability of industrial robots eliminate variability in production processes, reducing waste and improving overall manufacturing efficiency. Automated manufacturing solutions can achieve cycle times measured in seconds for complex operations that might require minutes when performed manually, directly translating to increased throughput and reduced production costs.

Manufacturing automation through industrial robotics enables optimization of production schedules and resource allocation by providing predictable, measurable performance metrics. Robotic systems can be programmed to operate at optimal speeds and paths, minimizing non-productive time and maximizing the utilization of production equipment and facilities throughout manufacturing processes.

Improved Quality and Precision

The inherent precision of industrial robotics enables manufacturing processes to achieve quality levels that are difficult or impossible to maintain through manual operations. Robotic automation systems can perform operations with repeatability tolerances measured in micrometers, ensuring consistent product quality across large production volumes and eliminating quality variations associated with human operators.

Industrial robots equipped with advanced sensor systems can perform real-time quality control and inspection tasks during production processes, identifying and correcting defects immediately rather than discovering them during final inspection. This capability significantly reduces scrap rates and rework requirements while improving overall manufacturing efficiency and cost-effectiveness.

The integration of robotic systems with statistical process control systems enables continuous monitoring and optimization of quality parameters throughout manufacturing automation implementations. Industrial robotics applications can automatically adjust process parameters to maintain optimal quality outcomes, ensuring consistent product performance while minimizing quality-related costs and customer complaints.

Enhanced Workplace Safety

Industrial robotics significantly improves workplace safety by removing human workers from dangerous environments and hazardous operations. Robotic automation systems can perform tasks involving toxic materials, extreme temperatures, or heavy loads without risk to human health and safety, creating safer working environments while maintaining production efficiency.

The implementation of collaborative robots enables safe human-robot interaction in manufacturing processes, with advanced safety systems that immediately stop robot motion upon detecting human contact or proximity. These safety features enable industrial robotics to work alongside human operators while eliminating the risks associated with traditional automated systems that required complete separation from human workers.

Manufacturing automation through industrial robotics reduces workplace injuries associated with repetitive motion, heavy lifting, and ergonomically challenging operations. By automating these physically demanding tasks, robotic systems enable human workers to focus on higher-value activities while reducing the risk of work-related injuries and associated costs.

Cost Reduction and ROI

Industrial robotics implementations typically deliver substantial cost savings through reduced labor costs, improved efficiency, and decreased waste and rework. While initial investment in robotic automation systems can be significant, most manufacturing automation projects achieve payback periods of 1-3 years through operational savings and productivity improvements.

The long-term operational costs of industrial robots are typically lower than equivalent human labor, particularly for operations requiring continuous operation or multiple shifts. Robotic systems do not require benefits, vacation time, or shift differentials, and their consistent performance eliminates costs associated with quality problems and production variability.

Manufacturing automation through industrial robotics enables manufacturers to reduce inventory requirements through improved production flexibility and faster changeover times. The ability to quickly reprogram robotic systems for different products reduces the need for large inventory buffers while enabling more responsive production processes that can adapt quickly to changing market demands.

Implementation Challenges and Solutions

Initial Investment and ROI Considerations

The implementation of industrial robotics requires significant upfront capital investment that can be challenging for smaller manufacturers or companies with limited resources. Manufacturing automation projects must be carefully evaluated to ensure that the expected benefits justify the initial costs and that adequate financial resources are available for successful implementation.

Successful robotic automation implementations require a comprehensive cost-benefit analysis that considers not only the direct costs of equipment and installation but also indirect costs such as training, facility modifications, and potential production disruptions during implementation. Industrial robotics projects should be evaluated based on the total cost of ownership rather than the initial purchase price to ensure realistic ROI projections.

Many manufacturers address the financial challenges of industrial robotics implementation through phased deployment strategies that spread costs over time while demonstrating value through early wins. Starting with specific applications that offer clear ROI can provide the financial justification and operational experience necessary for broader manufacturing automation deployments across production processes.

Workforce Training and Adaptation

The successful implementation of industrial robotics requires comprehensive workforce training programs that enable employees to operate, maintain, and program robotic systems effectively. Manufacturing automation changes job requirements and responsibilities, requiring investment in training programs that help workers develop new skills and adapt to evolving production processes.

Robotic automation implementations are most successful when they are positioned as tools that augment human capabilities rather than replace workers entirely. Training programs should emphasize how industrial robots can eliminate dangerous, repetitive, or physically demanding tasks while enabling workers to focus on higher-value activities such as quality control, maintenance, and process optimization.

The development of internal expertise in industrial robotics is critical for long-term success and may require partnerships with equipment vendors, educational institutions, or specialized training organizations. Manufacturing automation implementations benefit from having skilled technicians who can troubleshoot problems, optimize performance, and implement improvements without relying entirely on external support.

Integration with Existing Systems

Integrating industrial robotics with existing manufacturing automation systems can be complex, particularly in facilities with legacy equipment or diverse technology platforms. Robotic systems must be able to communicate with existing control systems, share data with manufacturing execution systems, and coordinate operations with other automated systems throughout production processes.

Successful integration of industrial robots requires careful planning and often requires upgrades to existing control systems, networks, and software platforms. Manufacturing automation projects should include comprehensive system integration planning that addresses communication protocols, data formats, and operational coordination requirements between robotic systems and existing equipment.

The implementation of standardized communication protocols and integration platforms can simplify the process of integrating industrial robotics with existing manufacturing systems. Modern robotic automation solutions increasingly support standard industrial communication protocols that facilitate integration with diverse production automation platforms and enable seamless data exchange across manufacturing processes.

Future Trends and Developments

Industry 4.0 and Smart Manufacturing

The evolution toward Industry 4.0 is fundamentally transforming industrial robotics applications through the integration of cyber-physical systems, IoT connectivity, and advanced data analytics. Smart manufacturing implementations utilizing connected robotic systems enable real-time optimization of production processes based on comprehensive data analysis and predictive modeling capabilities.

Industrial robotics in Industry 4.0 environments features autonomous decision-making capabilities that enable robotic automation systems to adapt automatically to changing conditions without human intervention. These intelligent manufacturing automation systems can optimize their own performance, predict maintenance requirements, and coordinate with other systems to maximize overall production efficiency.

The development of digital twin technology for industrial robots enables virtual simulation and optimization of robotic systems before physical implementation. This capability allows manufacturers to test and optimize manufacturing automation configurations virtually, reducing implementation time and risk while ensuring optimal performance of production processes.

Autonomous Mobile Robots

Autonomous mobile robots (AMRs) represent a rapidly growing segment of industrial robotics that is transforming material handling and logistics within manufacturing facilities. These robotic systems can navigate complex environments independently, transporting materials and products throughout production processes without fixed infrastructure such as rails or guide wires.

The integration of autonomous mobile robots with manufacturing automation systems enables flexible, adaptive material flow that can respond automatically to changing production requirements. AMRs equipped with advanced sensors and AI capabilities can optimize their routes dynamically, avoid obstacles, and coordinate with other robotic systems to maximize efficiency throughout manufacturing processes.

Smart manufacturing implementations increasingly utilize autonomous mobile robots for inventory management, quality control, and production support tasks. These industrial robotics applications enable more responsive and efficient production automation while reducing the labor requirements for material handling and logistics operations.

Human-Robot Collaboration Evolution

The evolution of collaborative robots is enabling increasingly sophisticated human-robot interaction in manufacturing environments. Advanced industrial robotics developments include robots with enhanced safety features, intuitive programming interfaces, and the ability to learn from human demonstrations, making robotic automation more accessible and adaptable to diverse production processes.

Future collaborative robotics applications will feature enhanced artificial intelligence that enables robots to understand human intentions and adapt their behavior accordingly. These developments will enable more natural and efficient collaboration between human workers and industrial robots in complex manufacturing automation scenarios that require both human creativity and robotic precision.

The development of wearable technology and augmented reality interfaces is creating new possibilities for human-robot collaboration in manufacturing processes. These technologies enable more intuitive control and monitoring of robotic systems while providing human operators with real-time information about production automation performance and optimization opportunities.

More Read:10 Must-Have Robotics Skills for Thriving in Modern Industries

Conclusion

Industrial robotics has fundamentally transformed modern manufacturing processes, delivering unprecedented levels of efficiency, precision, and flexibility across diverse industries. The evolution from simple programmable machines to intelligent, connected robotic systems has created new possibilities for manufacturing automation that continue to drive competitiveness and innovation.

As industrial robots become increasingly sophisticated through AI integration, advanced sensors, and IoT connectivity, they are enabling smart manufacturing implementations that optimize production processes in real-time while maintaining the highest quality standards.

The future of industrial robotics promises even greater integration with human workers through advanced collaborative robots, autonomous mobile systems, and intuitive programming interfaces that will make robotic automation accessible to manufacturers of all sizes. Companies that embrace industrial robotics and manufacturing automation technologies will be best positioned to thrive in an increasingly competitive global marketplace while creating safer, more efficient, and more sustainable production environments.